Focusing on the manufacturing of core components such as precision stamping, precision casting, precision injection molding, and machining, we have established long-term stable partnerships with global top 100 automotive parts companies like Bosch, BorgWarner, Magna, and Aisin, with our products ultimately applied in many well-known cars in the market.

Transmission system

The transmission system of a car is the core component for power transmission in the vehicle. It adjusts the torque and speed output from the engine through different gear ratios to adapt to various driving conditions. The transmission allows the car to maintain engine efficiency at different speeds while providing smooth acceleration and deceleration.

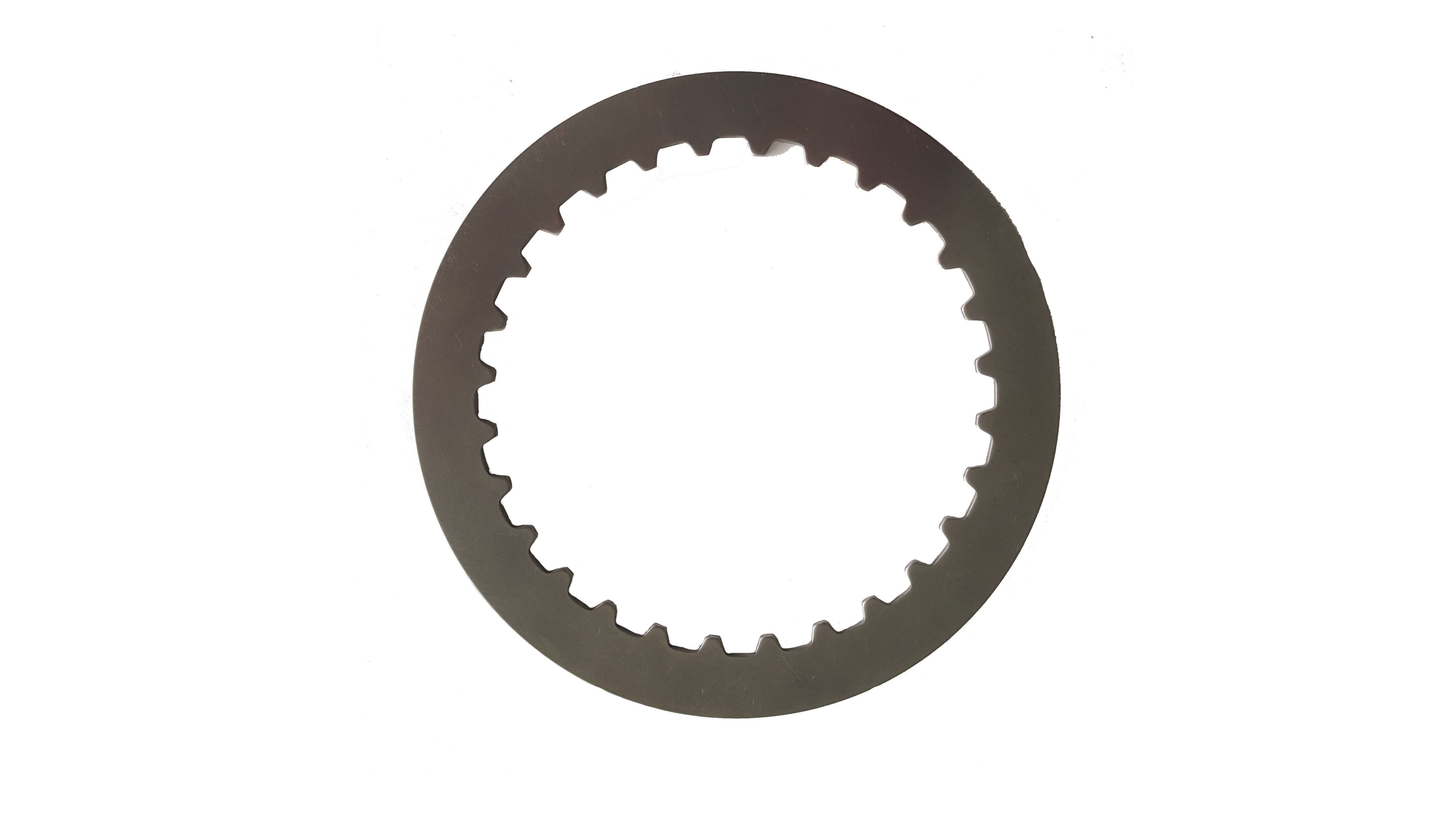

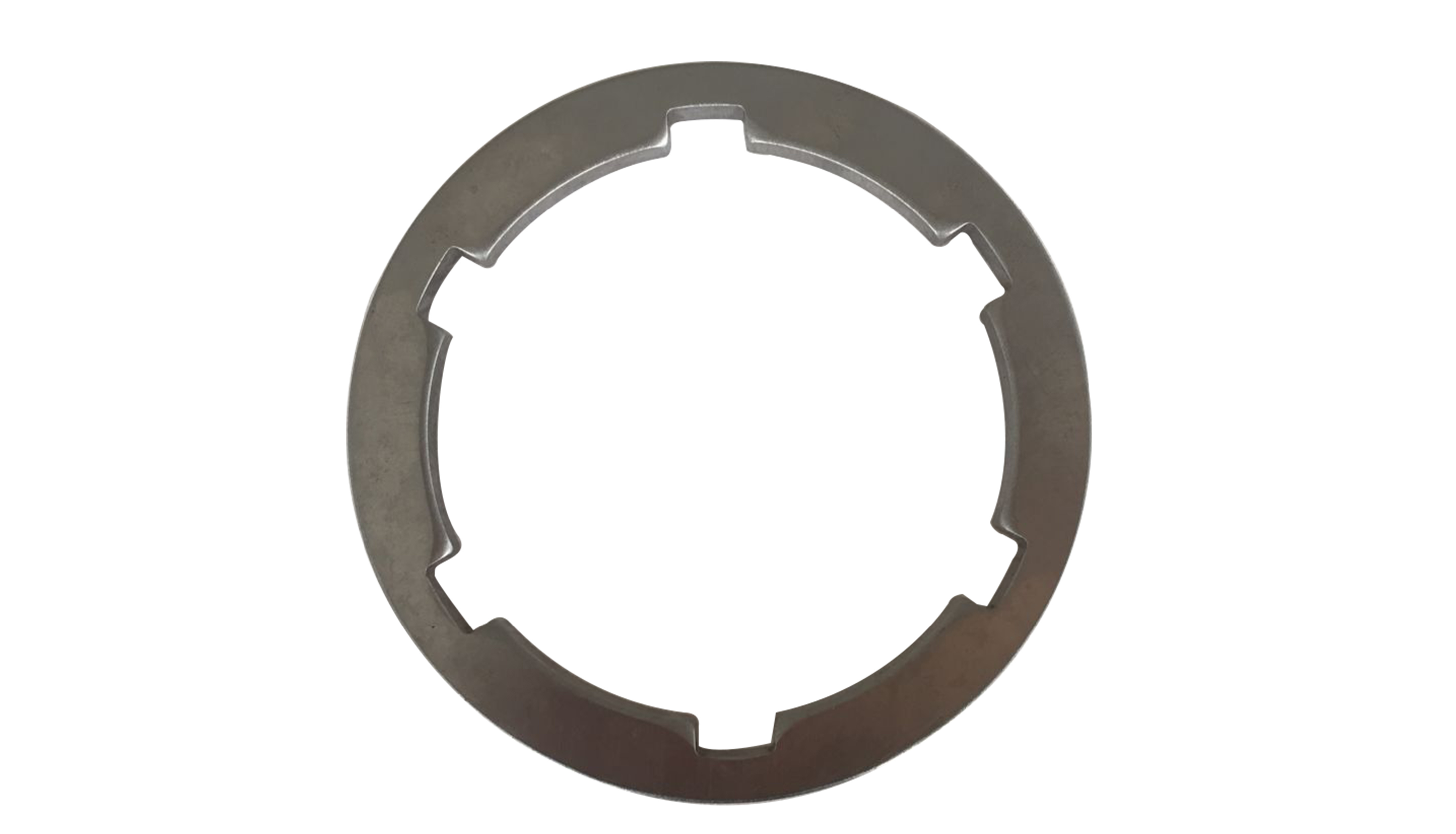

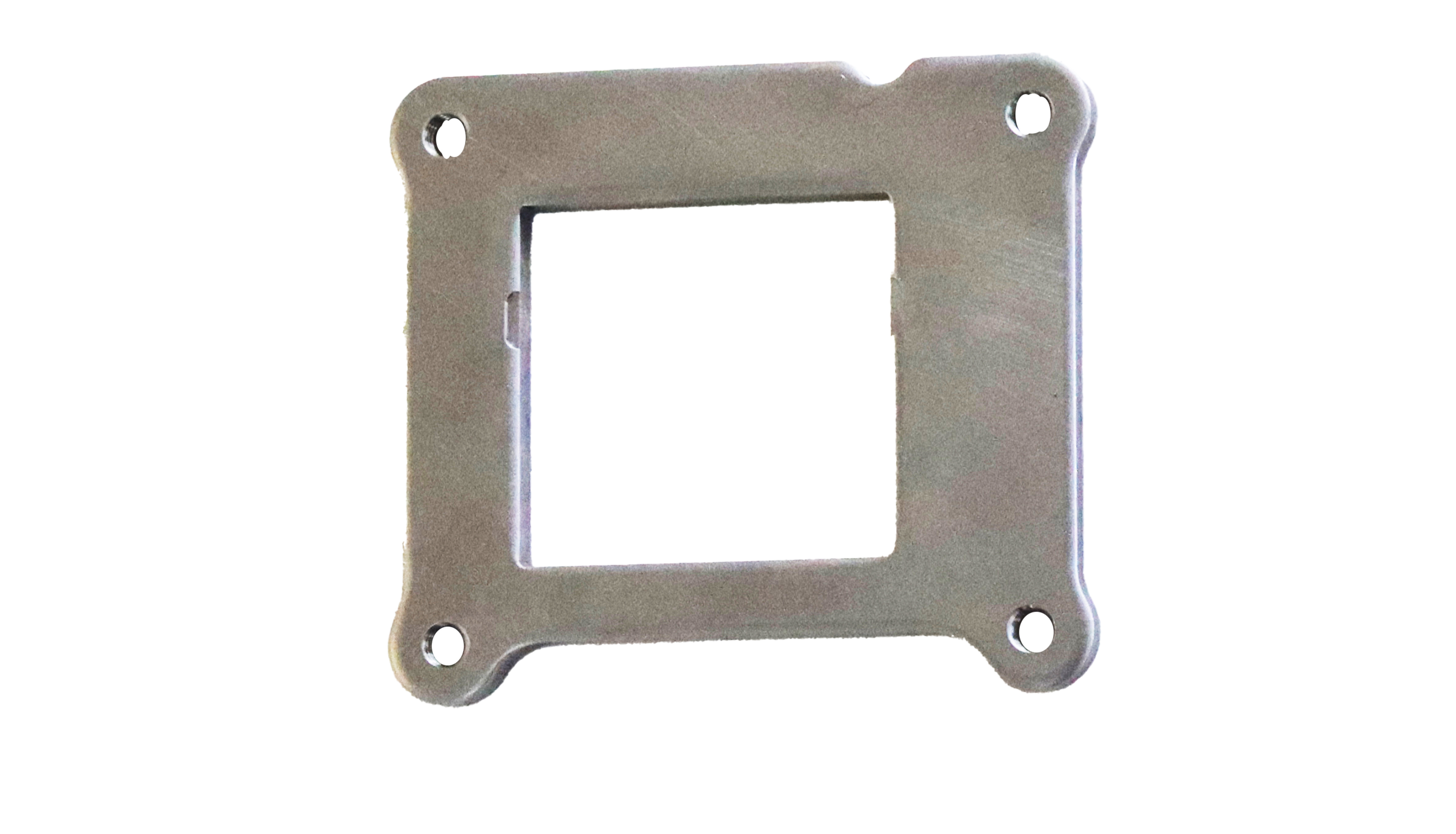

Clutch steel plate

The clutch steel plate is a crucial structural component in the automotive clutch system, typically made of high-strength spring steel plates, with each set containing two pieces, used to achieve smooth power transmission. One end of this steel plate is fixed to the clutch housing with rivets, while the other end is tightly connected to the pressure plate or punch with screws, ensuring effective power transmission and structural stability.

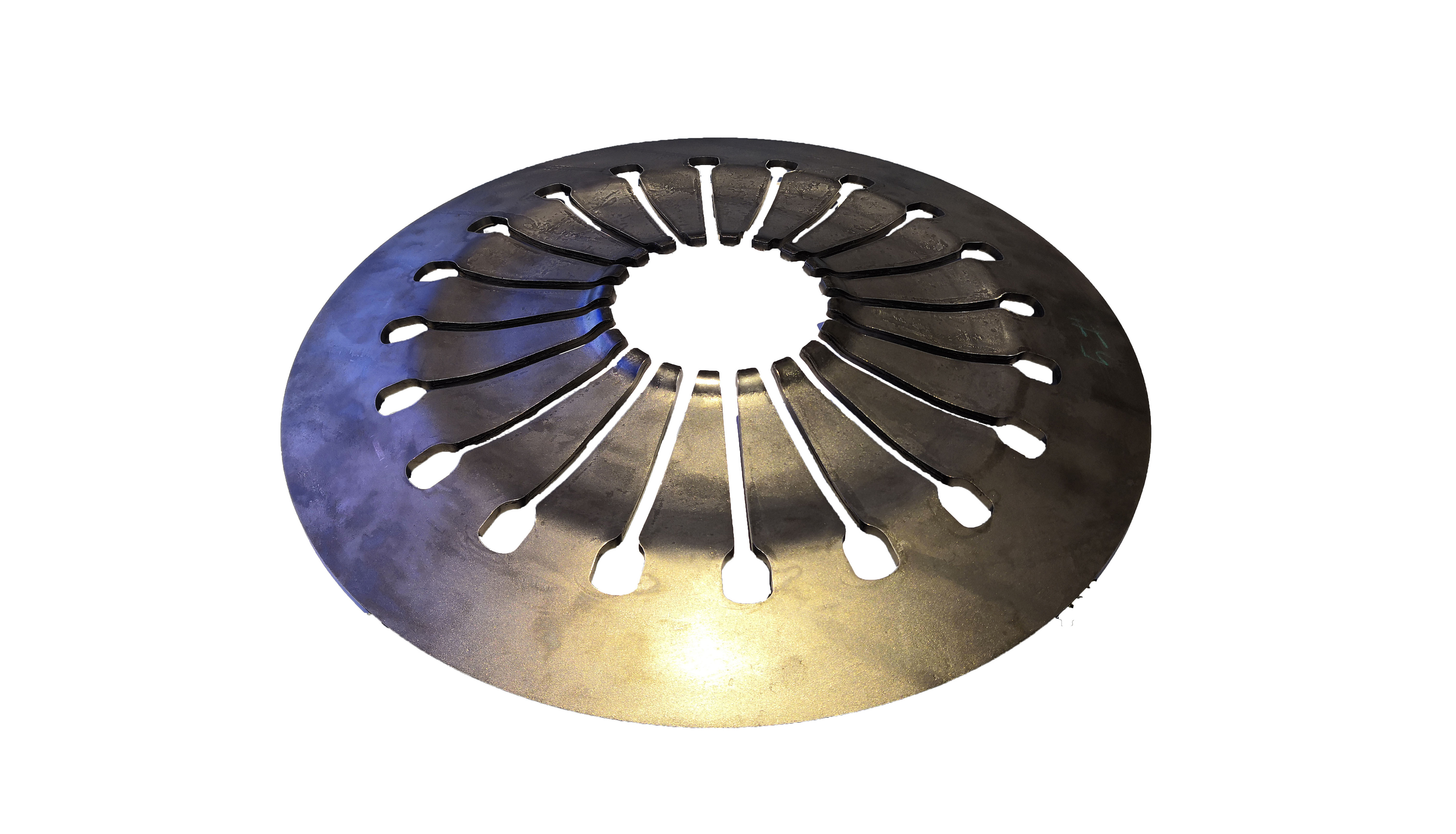

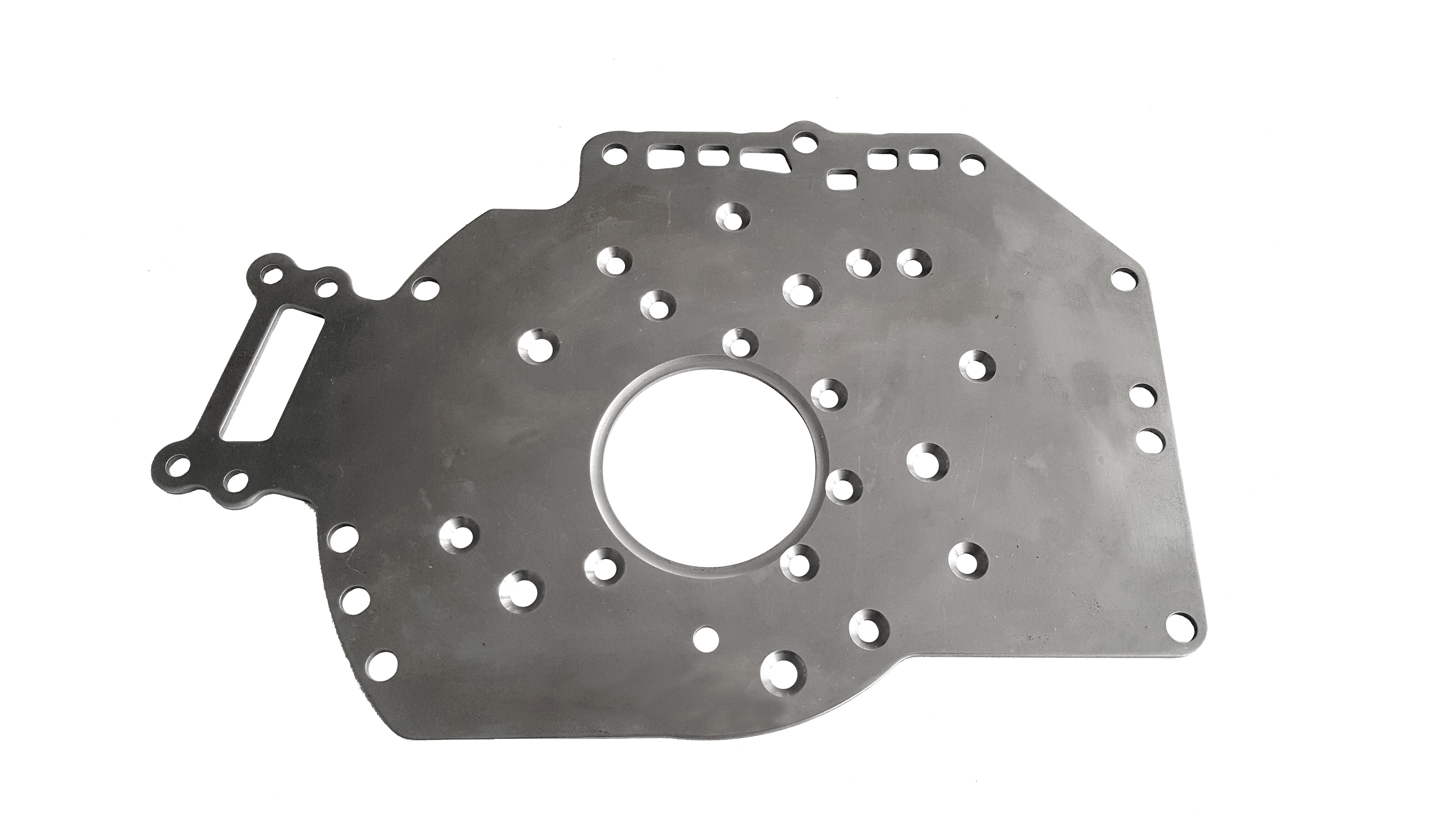

Drive cover plate

The drive plate is a core component of the car's clutch, typically connected to the engine's crankshaft, and serves as the active part of the clutch in power transmission. The drive plate generally consists of parts such as the flywheel, clutch cover, and pressure plate, which work together through precise design and manufacturing to achieve the clutch's function. The drive plate not only bears the responsibility of transmitting the engine's torque but also optimizes the clutch's performance through its structural design, such as reducing impact and improving engagement smoothness.

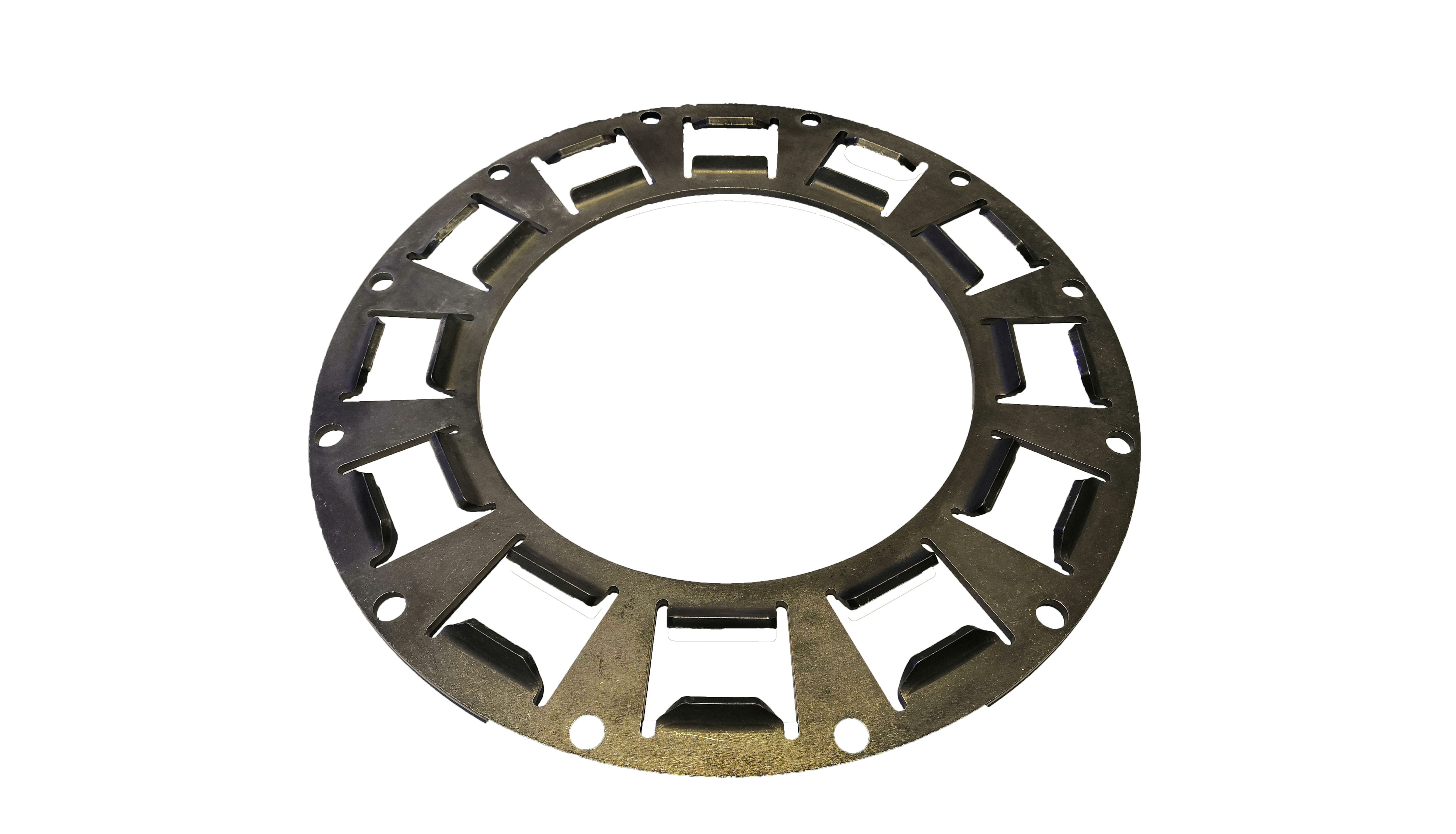

Clutch outer hub

The clutch outer hub is one of the crucial structural components in a car's clutch system. It is located in the driven part of the clutch and serves a dual role of supporting and transmitting power. As an important part of the driven disc, the clutch outer hub is usually made of high-strength metal materials, with its side walls uniformly distributed with tooth-like structures to cooperate with the friction plates and steel diaphragm to achieve stable power transmission. Its design fully considers the dynamic characteristics and material durability, ensuring that the clutch can maintain efficient and stable operation even under frequent use.

Oil pump partition

The fuel pump baffle is a key structural component in the automotive fuel system. It is usually located inside the fuel tank and is used to divide the tank into different areas for effective fuel management and optimized circulation. The fuel pump baffle is made of high-strength, corrosion-resistant materials, such as aluminum alloy or special plastics, to ensure its long-term stable operation in harsh fuel environments. Its design is sophisticated, effectively guiding fuel flow and improving the efficiency and performance of the fuel system.

Shift lock plate

The shift lock plate in the vehicle's shifting mechanism is an important component of the shift locking device. It mainly serves to lock and unlock the gear position, ensuring the accuracy and safety of the transmission during the shifting process.

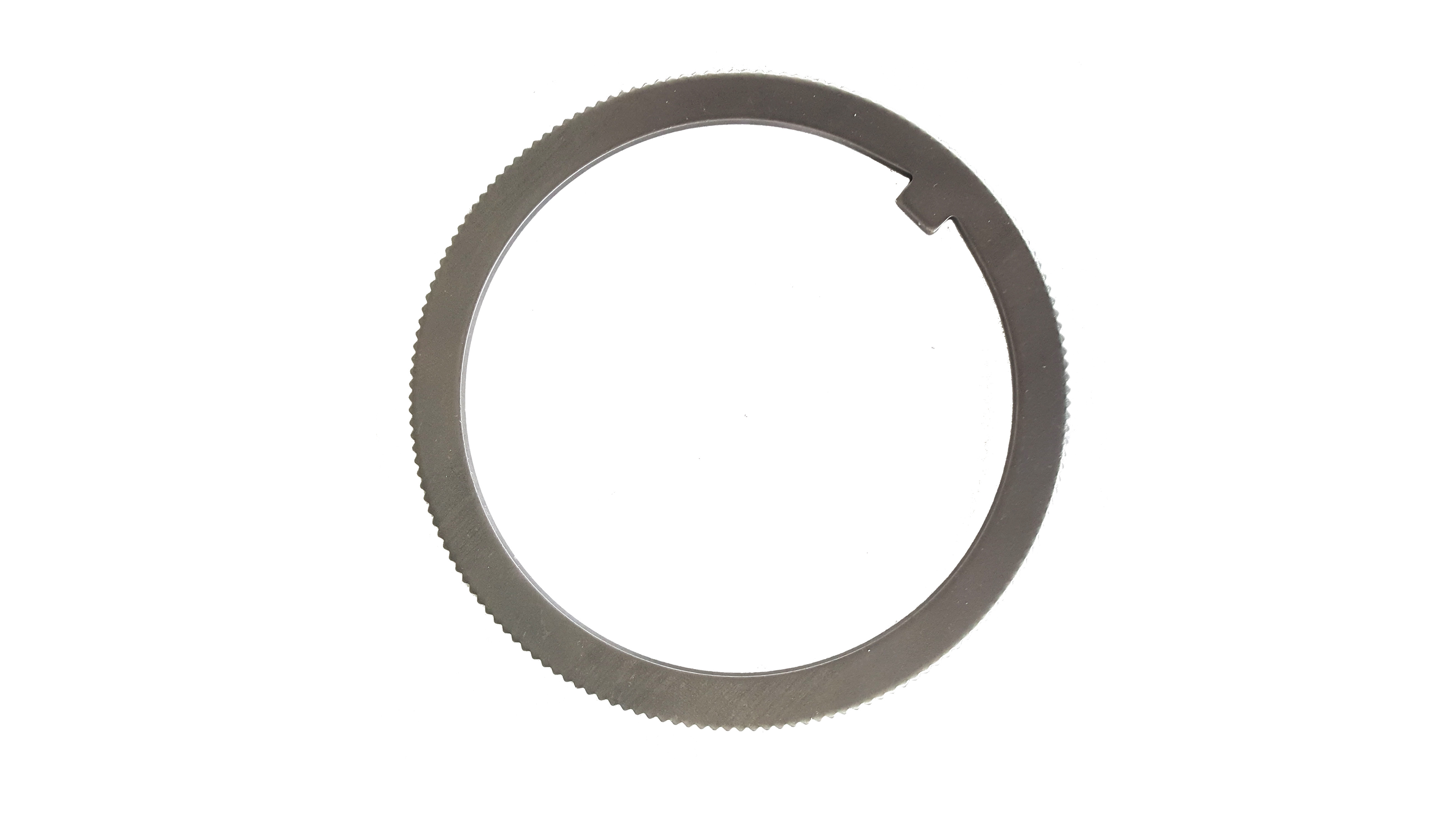

Synchronizing ring - coupling teeth

The coupling teeth are a key structural component in automotive synchronizers. They typically have a conical surface and are fixed to the gear or spline hub, working in conjunction with components such as the synchronizer ring or engagement sleeve. The design of the coupling teeth takes into account the needs for friction and synchronization, with their conical surfaces able to closely contact the conical surfaces of the synchronizer ring, achieving speed synchronization through friction. This design allows the coupling teeth to smoothly engage with the corresponding components during gear shifting, ensuring continuity and smoothness in power transmission.

Planetary gear

Planetary gears, also known as planetary gear sets, are a complex and sophisticated component in automotive transmission systems. They consist of four core components: the sun gear, multiple planet gears, the ring gear, and the planet carrier. This unique structure allows planetary gears not only to achieve the 'self-rotation' effect of traditional fixed-axis gears but also to perform 'revolution' as the planet carrier orbits around the sun gear or other gears. This operating principle is similar to the movement of planets in the solar system, hence the name planetary gear set. Due to their characteristics such as power distribution, high load capacity, and large transmission ratios, planetary gears are widely used in automotive transmissions, hybrid systems, and the new energy sector.

Planetary rack

The planet carrier is the core structural component of the automotive planetary gear transmission system, designed intricately and playing a key role. The planet wheel shafts or bearings are mounted on the planet carrier, making it an important carrier for supporting and transmitting power. The structure of the planet carrier is complex and must meet requirements such as lightweight, good rigidity, and ease of processing and assembly to ensure the stability and efficiency of the transmission system. Common structural forms include double-sided plate integrated, double-sided plate separated, and single-sided plate types, to accommodate different transmission needs and application scenarios.

Engine system

The requirements for engine components are very strict, needing to have high strength, high hardness, high heat resistance, good wear resistance, and corrosion resistance, while also ensuring high precision in dimensions and surface smoothness to guarantee the efficient, stable, and durable operation of the engine.

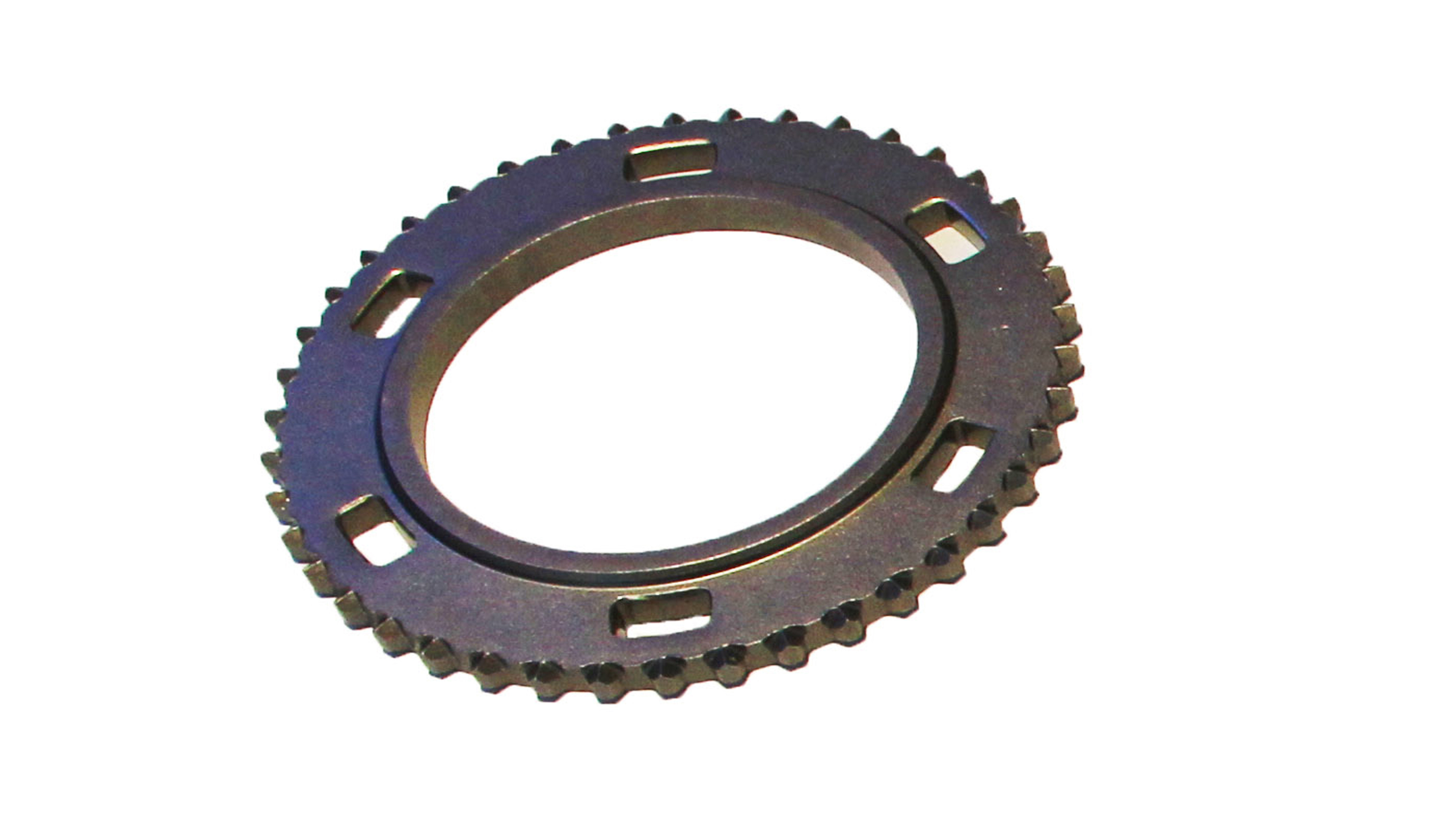

Sprocket

The sprocket mainly consists of parts such as teeth, body, and hub. The teeth are the key part that engages with the chain, and their shape and size directly affect the efficiency and stability of the transmission. The body is the main part of the sprocket, used to support the teeth and transmit power. The hub is used to install the sprocket, and is usually connected to other components of the engine (such as the crankshaft, camshaft, etc.).

Motor casing

The motor in a car engine usually refers to the starter motor, which is an important component of the car's starting system. It is responsible for converting the electrical energy from the battery into mechanical energy to start the engine. Its outer casing is known as the motor housing.

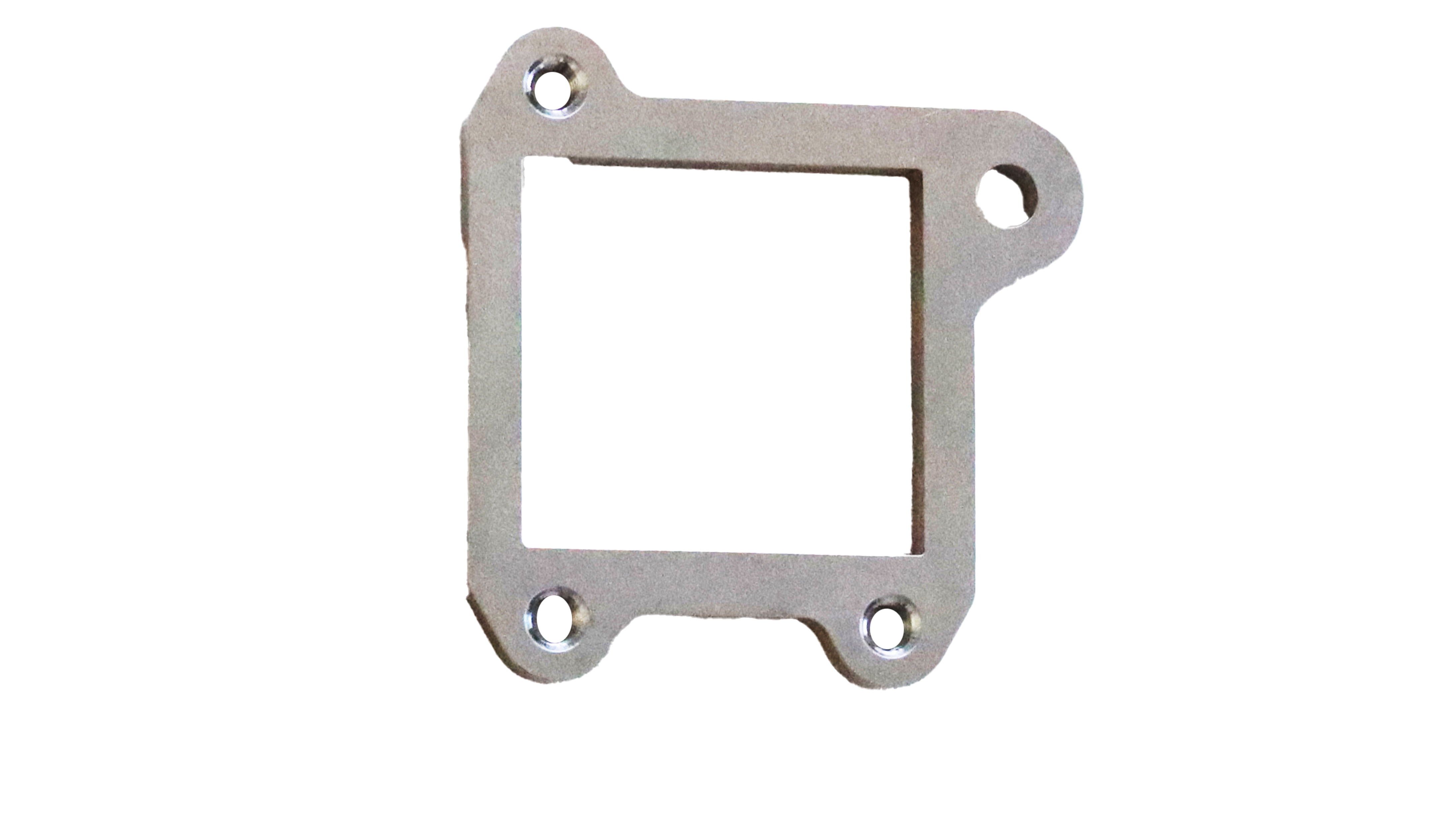

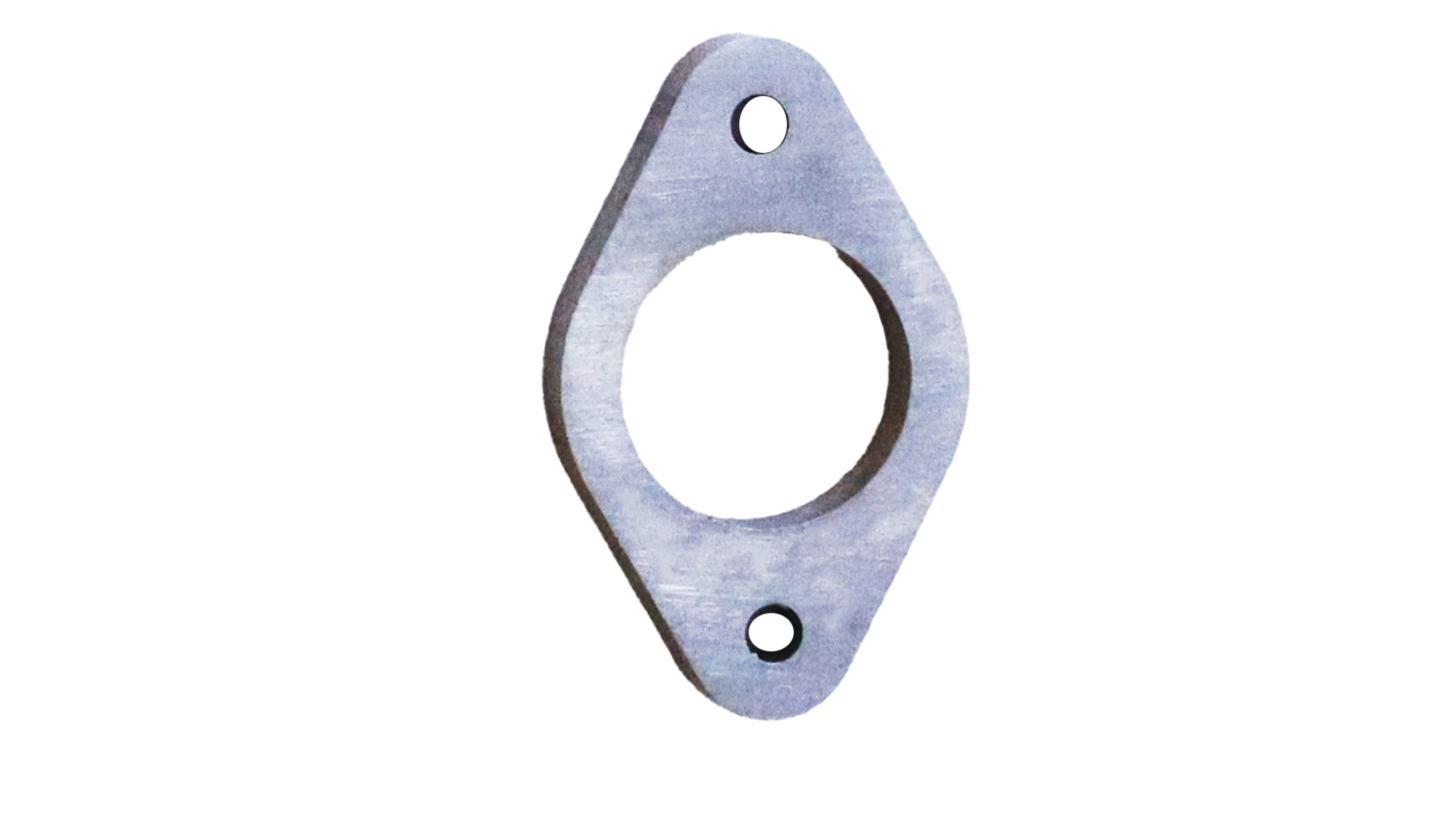

Flange

The exhaust flange is a key structural component in the automotive exhaust system. It serves as a connecting part for pipe fittings and is usually located at the interface of different components of the exhaust system. The exhaust flange securely connects two or more pipe fittings together using bolts or other fasteners, ensuring the sealing and stability of the exhaust system. Its design takes into account the working environment of high temperature, high pressure, and corrosive gases, so it is often made of high-temperature and corrosion-resistant materials, such as stainless steel or alloy steel.

Oil pan

The oil sump is located at the bottom of the engine: it can be disassembled and serves as the outer shell of the crankcase seal for the oil reservoir. The oil sump is mostly made of thin steel plates, while more complex shapes are generally cast from cast iron or aluminum alloy. It is equipped with baffles inside to prevent oil surface agitation caused by the jolting of the diesel engine, which helps in the sedimentation of impurities in the lubricating oil. A dipstick is installed on the side to check the oil level.

Seat system

The seat components need to have sufficient strength and durability to meet the requirements for load-bearing, adjustment, and long-term use of the seat.

Seat angle adjuster

The seat angle adjuster is a key adjustment mechanism in car seats. It is installed in the connection area between the seat back and the seat cushion, used to adjust the angle of the seat back to meet the seating needs of different passengers. The seat angle adjuster typically consists of parts such as the backrest connection plate, seat connection plate, core component, handwheel or adjustment handle, and return spring, featuring a compact structure and powerful functionality.

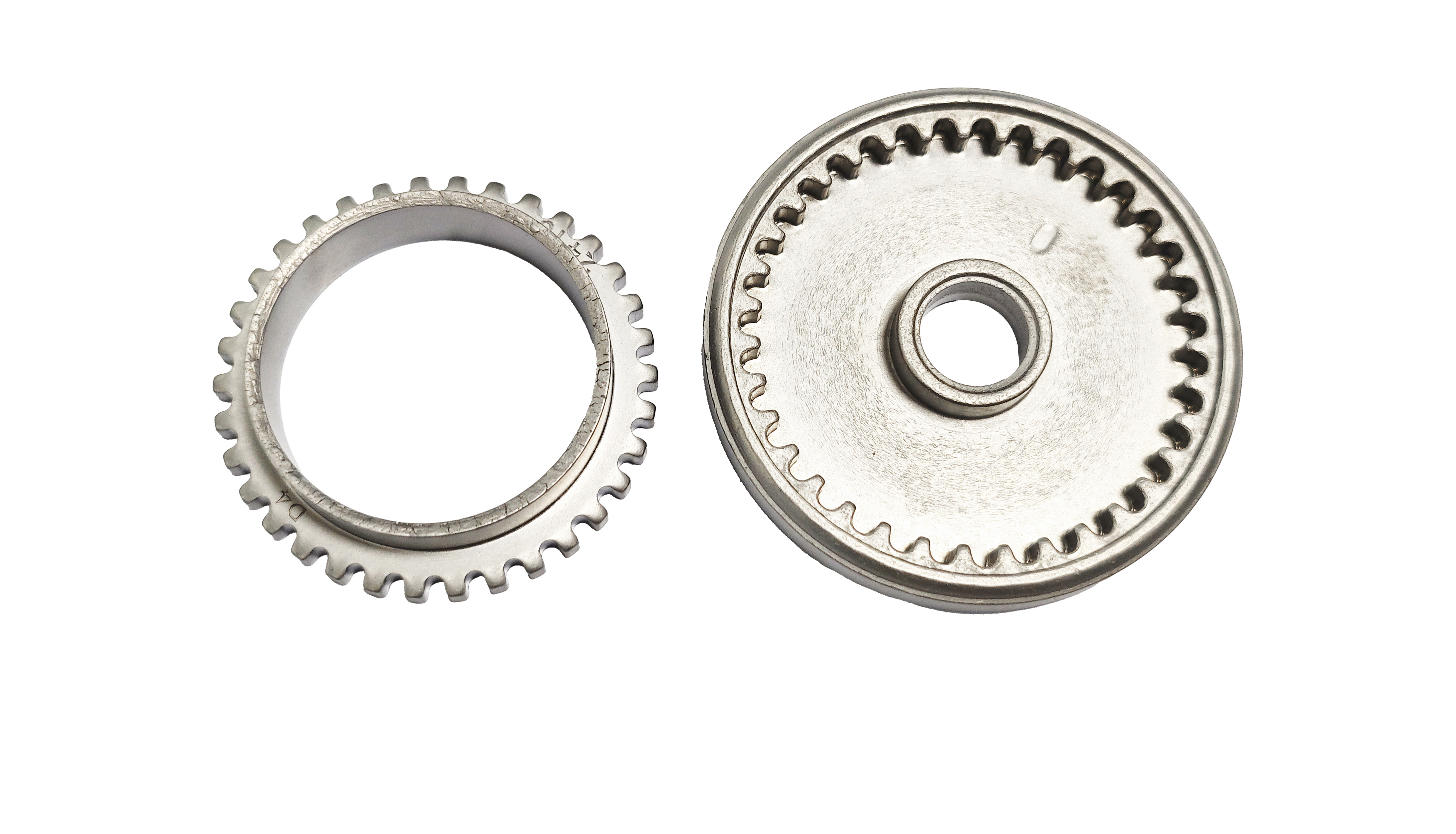

Seat height adjustment gear

The seat height adjustment gear rack is a key component in the car seat adjustment mechanism. It is usually connected to the seat lifting mechanism and serves as the driving end of a four-bar linkage or similar mechanism. By rotating, it drives the lifting of the seat frame or cushion, thus achieving the adjustment of seat height. The seat height adjustment gear rack is made of high-strength materials and features a precise tooth shape design to ensure smooth engagement and efficient transmission with the driving mechanism (such as motor gears).

Seat sun gear

A circular or approximately circular gear with multiple evenly distributed teeth, which serves as a core driving component in seat angle adjusters, sliding rails, or other adjustment mechanisms. This component achieves precise adjustment of parameters such as the angle of the seat backrest and the front and rear position by engaging with other gears or racks.

Steering system

The requirements for the components of the steering system include high precision, high strength, good wear resistance, and corrosion resistance. At the same time, it is necessary to ensure the fit precision between the components and the effectiveness of the gap adjustment mechanism, in order to ensure the sensitivity, stability, and safety of the steering system, meeting the driver's precise control of the car's steering.

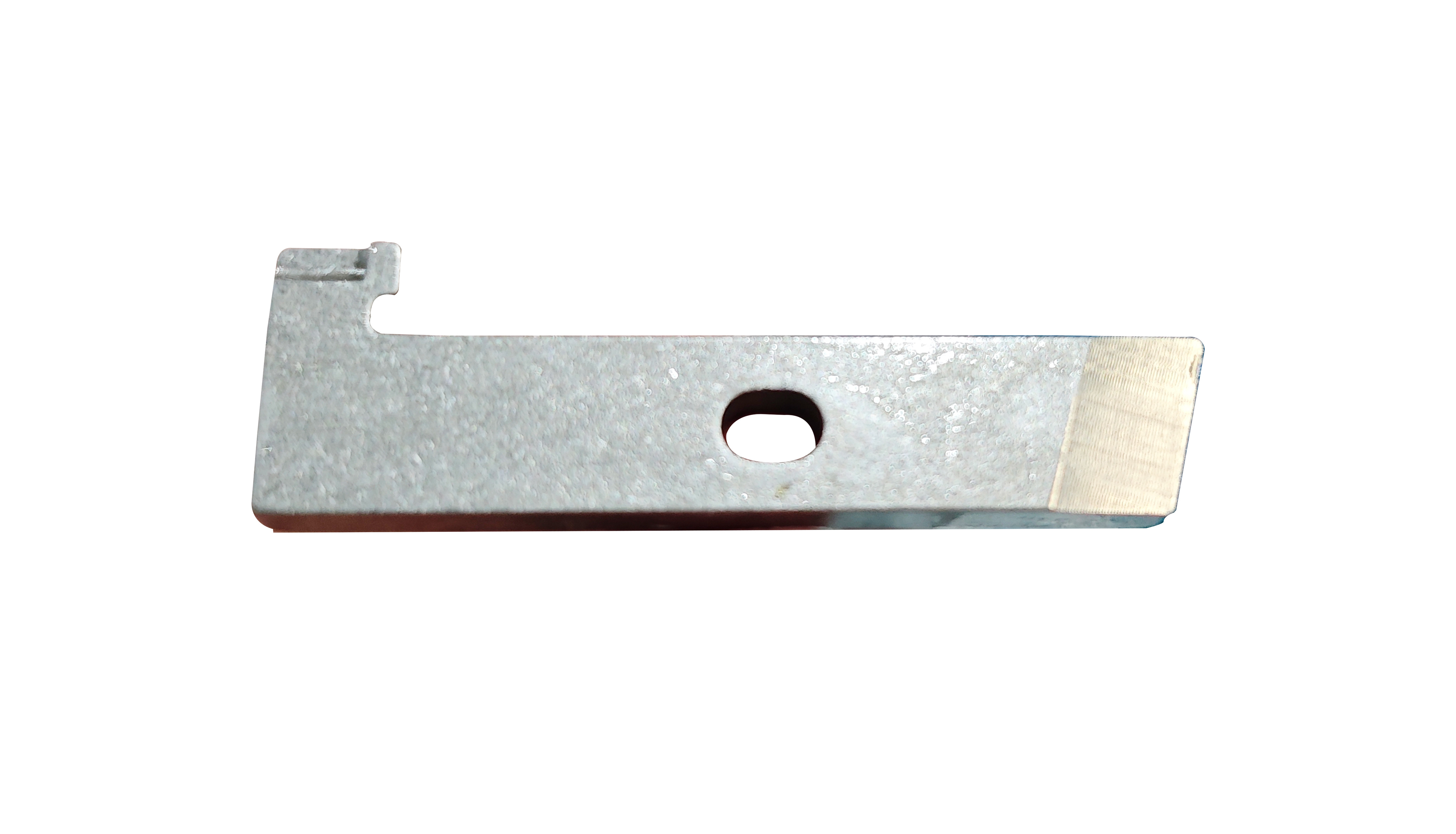

Steering wheel lock tongue

The steering wheel lock tongue is an important safety component in the car's steering system. It is usually used in conjunction with the steering wheel locking mechanism to physically restrict the rotation of the steering wheel, thereby preventing the vehicle from being started or moved without authorization. The steering wheel lock tongue is made of high-strength materials, characterized by its durability and ease of operation, making it an important part of the car's anti-theft system.

Turning gasket

The steering spacer is a small yet crucial structural component in the automotive steering system. It is typically located at key contact points or friction surfaces of the steering mechanism, such as between the steering column and the steering gear, or between the steering tie rod and the steering knuckle. The steering spacer is made of wear-resistant, corrosion-resistant, and somewhat elastic materials, such as rubber, plastic, or special alloys, designed to reduce direct friction between components and improve the operational efficiency and lifespan of the steering system.

Steering bracket

The steering bracket is a key structural component in the automotive steering system. It serves as the foundational support part of the steering mechanism, connecting critical components such as the steering column, steering gear, and the vehicle body. Steering brackets are typically made from high-strength materials to ensure they can withstand various forces and moments from the steering system during vehicle operation, maintaining the stability and reliability of the steering system.

Parking system

The requirements for the components of the parking system include high strength, high precision, good wear resistance, and corrosion resistance. At the same time, the components must be able to operate normally within a certain temperature range, possess good reliability and safety, ensure stable parking under various driving conditions, and be easy to operate with strong practicality.

Locking block

The parking lock block is an important structural component in the vehicle parking system. It usually works in conjunction with parts such as the parking pawl and parking ratchet to provide additional locking force when the vehicle is parked, ensuring that the vehicle can be stably parked in the designated position. The design of the parking lock block takes into account material strength, wear resistance, and compatibility with other components of the parking system to ensure reliable long-term operation.

Parking push-pull rod

A key actuating component in the vehicle parking system, it is responsible for converting the parking signal into mechanical motion under the driver's operation, thereby driving components such as the parking pawl to engage with the parking ratchet, achieving stable parking of the vehicle. The parking push rod typically consists of a rod body, push rod head, return spring, and other parts, designed to be sophisticated and compact, capable of efficiently completing the parking action in a limited space.

Parking ratchet

The parking ratchet is a core component of the vehicle parking system, usually used in conjunction with the parking pawl to achieve stable parking of the vehicle. It is typically designed as a circular or nearly circular metal piece with multiple tooth slots, which are used to engage with the claw part of the parking pawl. The parking ratchet is installed in an appropriate position on the transmission or wheel, with sufficient strength and rigidity to withstand the forces and moments generated during parking.

Parking claw

The parking pawl is a key component in the vehicle parking system, usually installed at an appropriate position in the transmission or wheel, and it engages with a ratchet or other corresponding parts to achieve the vehicle's parking function. It consists of several parts, including the pawl, spring, mounting plate, and handle, featuring a compact structure and easy operation. The material of the parking pawl is often selected from high-strength, wear-resistant metal materials to ensure it can withstand sufficient force and maintain stable performance during use.

Car door components

The requirements for car door components include high precision in dimensions and fit to ensure smooth operation and good sealing of the door; components must have sufficient strength and rigidity to meet safety and durability needs; surface quality must be smooth and free of defects to enhance the overall appearance of the vehicle; at the same time, materials must have good corrosion resistance to adapt to various climatic conditions.

Precision punching door lock

The car door lock is a complex and precise mechanical system, mainly composed of a large body (or large bracket), a small body (or small support), a pull plate, as well as key components such as the lock tongue and lock cylinder. These components work closely together to achieve various functions of the car door, including locking, unlocking, anti-lockout, child lock, and internal locking/unlocking. The design of the door lock fully considers safety and convenience, making it an important part of the car's safety system.