As a professional manufacturer of bipolar plates in the hydrogen power field, the company's products are widely used in the automotive, marine, aviation, and energy storage sectors. They cover components in the hydrogen field such as hydrogen fuel cell bipolar plates, composite end plates, etc. (using processes like metal sheet stamping, flexible graphite molding, nano-ceramic coating, and machining injection molding), as well as alkaline electrolyzers (ALK), PEM electrolyzers, and solid oxide (SOEC) electrolyzer bipolar plates in the hydrogen production field, and all-vanadium flow battery graphite bipolar plates in the energy storage field.

Hydrogen energy applications

The fuel cell bipolar plates need to meet requirements such as high electrical conductivity, good gas tightness and mechanical strength, excellent corrosion resistance, precise flow field design, efficient forming and manufacturing technology, advanced welding processes, reliable sealing components, and cost control, to ensure the stability and economy of the plates under harsh conditions such as high temperature, high pressure, and high humidity, achieving efficient and stable operation of the fuel cell.

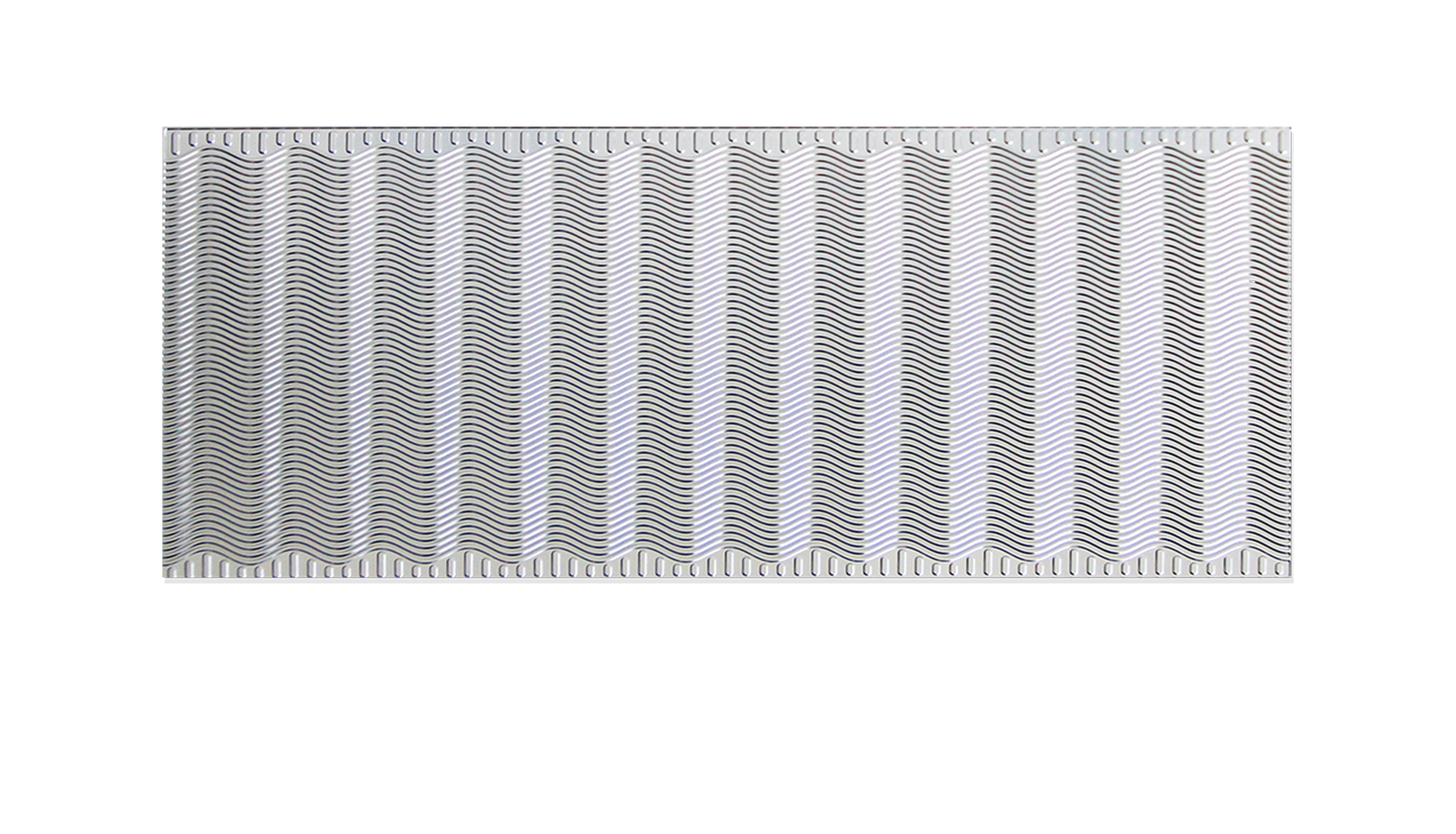

Metal bipolar plate

It mainly serves to support the membrane electrode, separate the oxidant and reductant, collect current, and provide channels for the coolant, while also possessing good thermal conductivity, electrical conductivity, and mechanical strength. Its advancement lies in its high precision, smooth product surface, fine dimensions, accurate positioning, as well as strong manufacturing capability and adaptability.

Public terminal board

Mainly responsible for the task of shell packaging, protecting the internal structure of the battery, and ensuring the integrity and stable operation of the battery.

Anode composite end plate

As the anode connection part of the hydrogen fuel cell, its main function is to transfer load electrons and prevent the direct mixing of hydrogen and oxygen to avoid combustion.

Cathode composite end plate

In hydrogen fuel cells, the connection part that serves as the cathode primarily functions to guide the flow of oxygen to the cathode catalyst layer and ensure the effective discharge of reaction products.

Hydrogen production field

Electrolytic hydrogen production electrode plates require high electrical conductivity to ensure efficient current transmission, excellent corrosion resistance to withstand the chemical environment during the electrolysis process, good mechanical properties to maintain structural stability, precise flow field design to optimize electrolyte flow and gas distribution, and strict airtightness requirements to prevent gas leakage and cross-contamination. These requirements collectively ensure the efficiency, safety, and economy of the electrolytic hydrogen production process.

SOEC solid oxide electrolysis cell electrode plate

SOEC solid oxide electrolysis cell electrode plates not only serve as electrodes to convert electrical energy into chemical energy to drive water decomposition, but also are responsible for thermal management in high-temperature environments, hydrogen-oxygen separation to ensure the safety and efficiency of gas collection, while providing mechanical strength and structural support to ensure the stability and durability of the electrolysis cell.

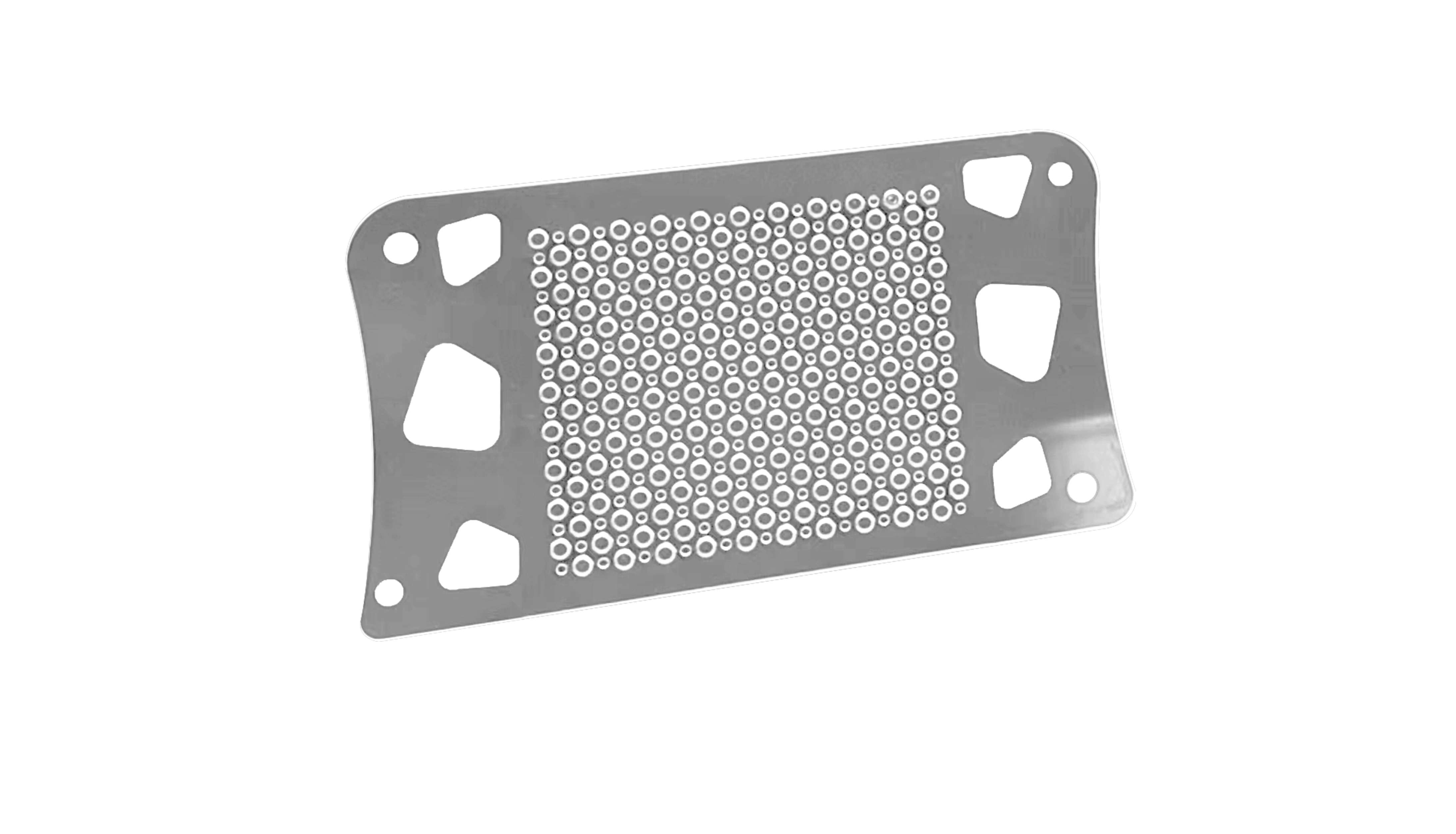

PEM electrolyzer cell electrode plate

The PEM hydrogen generation electrode plate plays a key role in the proton exchange membrane (PEM) water electrolysis process. It is responsible for collecting and conducting current to the electrodes to drive the water electrolysis reaction, producing hydrogen and oxygen.

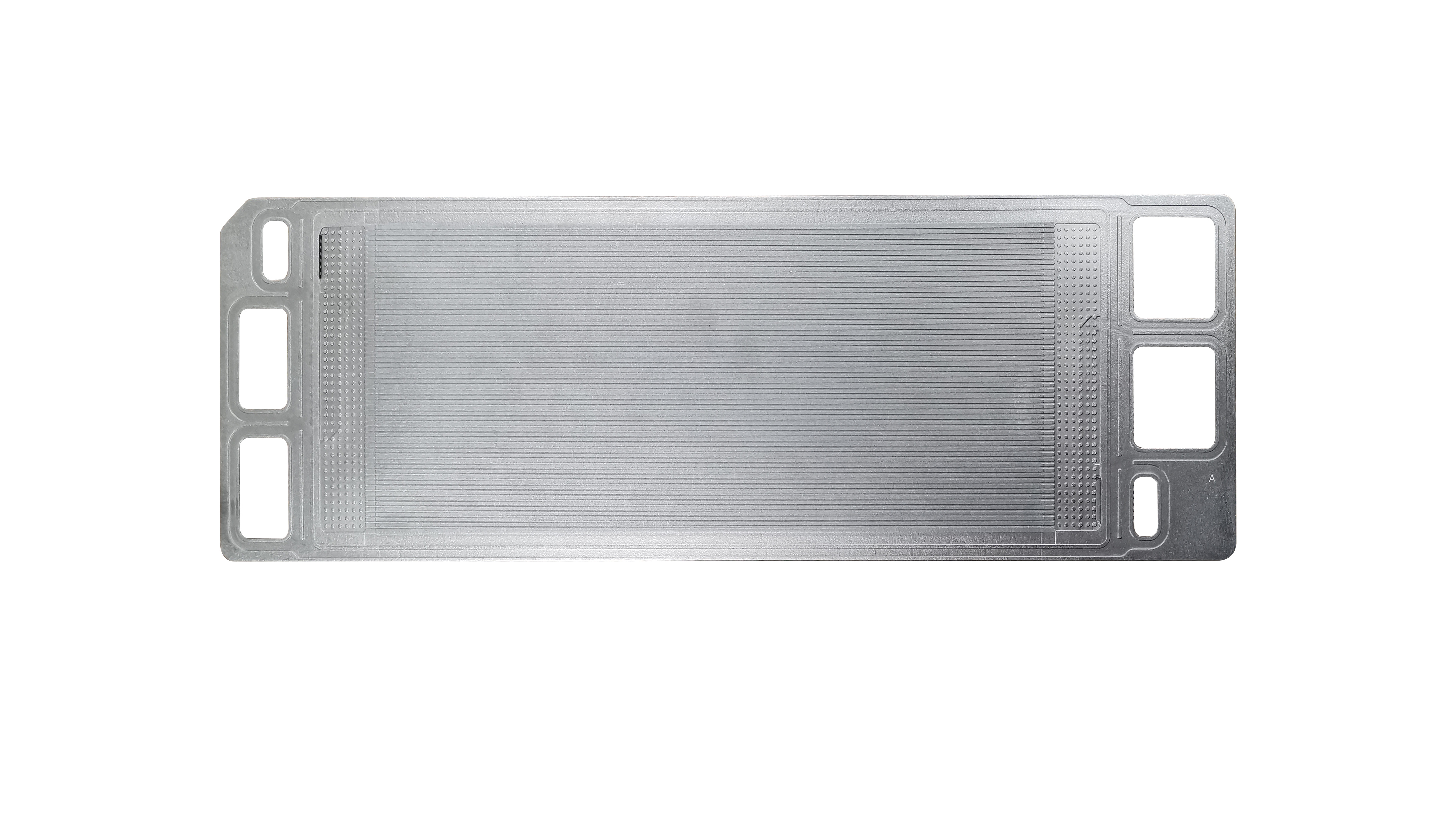

ALK alkaline electrolyzer electrode plate

ALK alkaline electrolyzer electrode plates are key components in alkaline water electrolysis for hydrogen production. Their structural design and material selection help improve electrolysis efficiency and the purity of hydrogen, while ensuring the safety and stability of the hydrogen production process.

Energy storage field

The energy storage field mainly includes components such as all-vanadium flow battery graphite bipolar plates; it has rich experience and capability in complex flow field design for fuel cells, able to meet various design requirements of flow batteries.

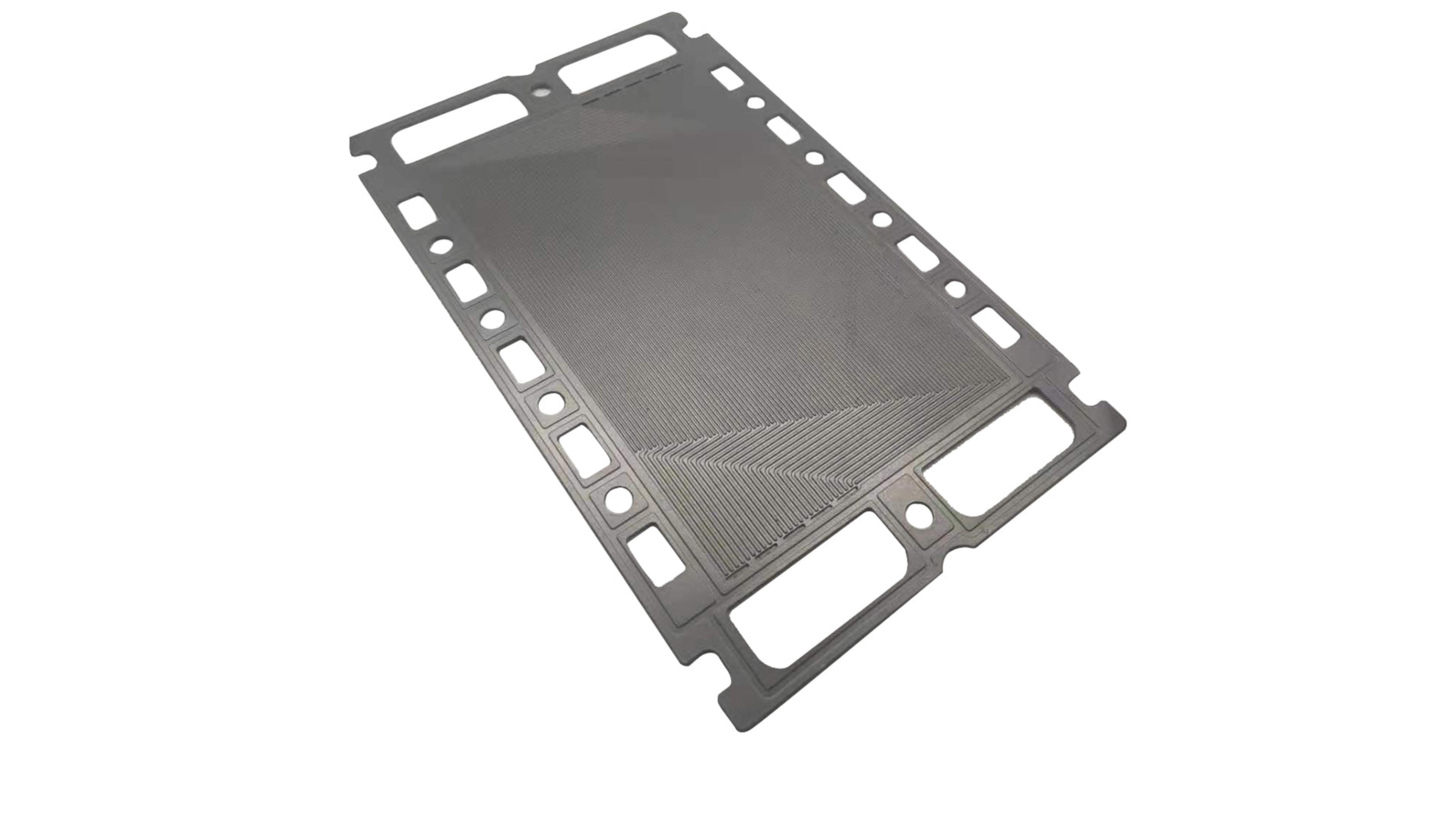

Graphite bipolar plate

Graphite bipolar plates play a crucial role in vanadium redox flow batteries. They are responsible for collecting and conducting current during the battery's charge and discharge processes, providing effective mechanical support for the membrane and electrodes, connecting multiple single cells, and preventing the mixing of positive and negative electrolyte and direct contact between the electrodes. Due to their good conductivity, low density, and excellent corrosion resistance, graphite bipolar plates are widely used in vanadium redox flow batteries.