Bipolar plates for alkaline electrolyzers: The core driving force in the hydrogen energy field

2024.06.28

Product Information

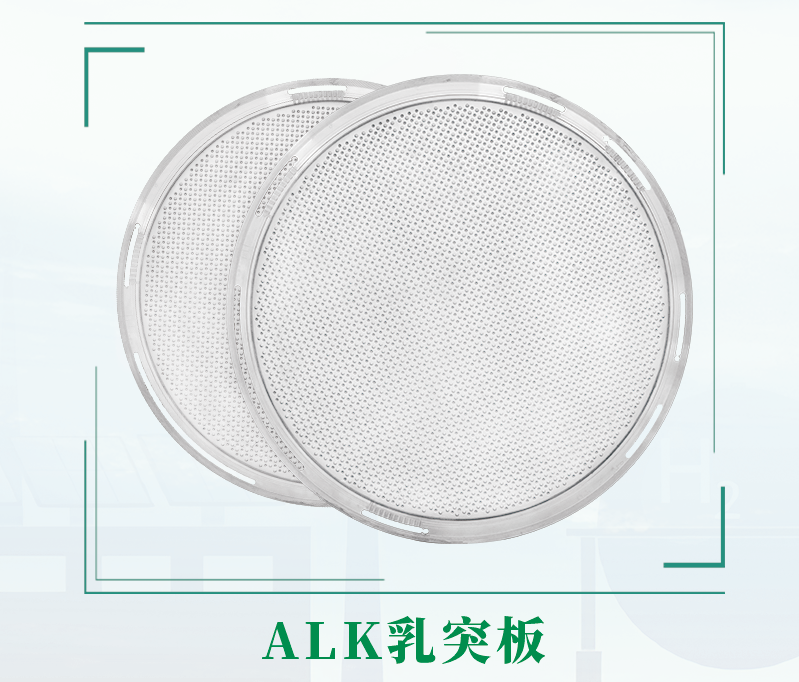

Alkaline electrolysis hydrogen production technology, as a mature and cost-effective technological path in the field of green energy, occupies an important position among many green hydrogen projects. Among them, the nipple plate, with its unique spherical convex-concave surface structure, effectively reduces contact resistance and promotes uniform distribution of alkaline solution, thereby effectively reducing energy consumption and becoming a widely used type of electrode plate in the market.

Boyuan (Shandong) New Energy Technology Development Co., Ltd. focuses on the research and design of hydrogen energy electrode plates and structural components, establishing a fully automated production line covering key processes such as ALK nipple plate stamping, precision manufacturing of electrode frames, and laser welding, ensuring high efficiency in the production process and precision in product processing.

High-end equipment ensures excellent processing capability.

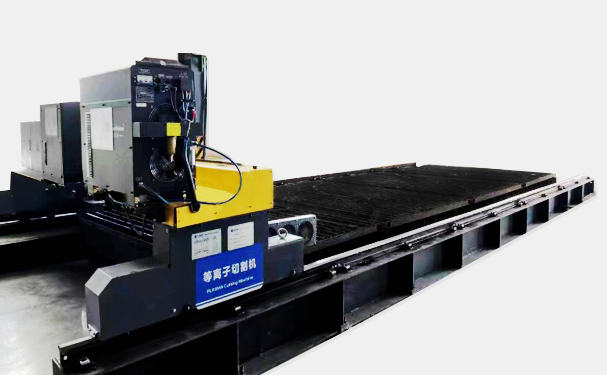

The company is equipped with industry-leading processing equipment and automated production lines, including a 25,000-ton heavy-duty wire winding press, CNC plasma cutting machines, vertical lathes, and gantry five-axis machining centers, ensuring processing accuracy and production stability. The 25,000-ton heavy-duty wire winding press adopts a wire winding prestressed structure and applies energy storage variable frequency technology, featuring ultra-high pressure boosting capabilities and high guiding accuracy, demonstrating unique advantages in processing large and high-precision products.

In the electrode frame processing stage, advanced technologies such as round forming, precision welding, vertical lathe processing, and high-precision laser welding are comprehensively applied to ensure the accuracy and quality of the electrode frame, achieving one-stop service from raw material procurement to finished product delivery.

Production process strives for micron-level precision.

By optimizing the manufacturing process of the nipple plate and strictly implementing quality control standards, high precision is achieved.Laser cutting systemControlling the diameter error within ±0.2 millimeters. In addition, through intelligent stamping and edge trimming processes,warpageis controlled within 0.5 millimeters, thereby improving production efficiency and product consistency.

In the manufacturing process of the electrode frame blank, every step from plasma cutting, pre-bending, round forming to welding and shaping can be completed with high quality, ensuring that the inner diameter, outer diameter, flatness, and thickness meet the requirements before machining.

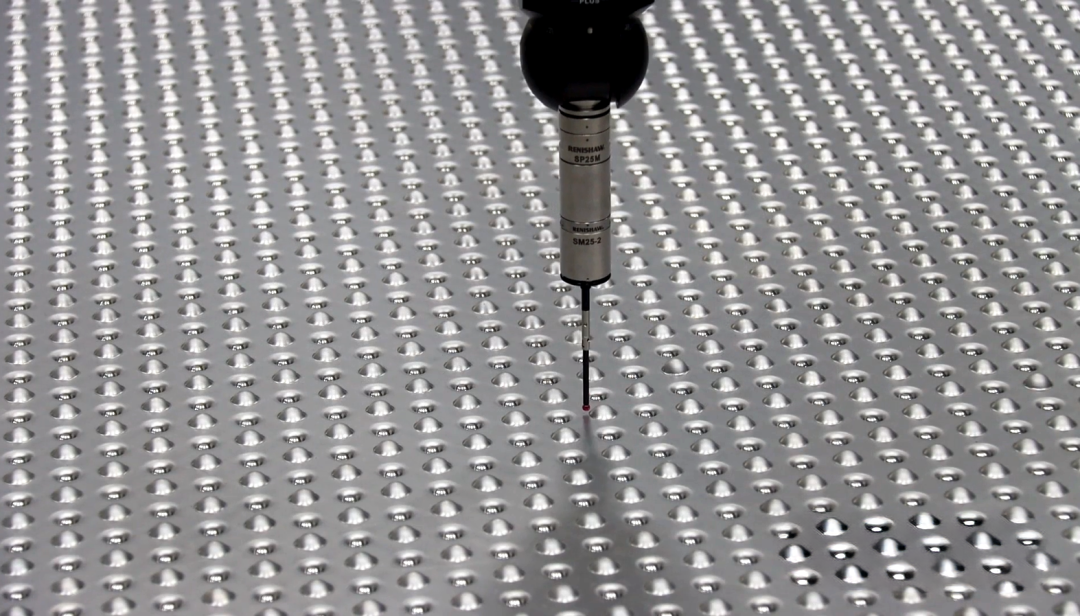

Intelligent detection system achieves comprehensive quality monitoring.

To ensure product quality, Boyuan has established an intelligent detection system and introduced a series of high-end testing equipment, such as large-scalethree-coordinate measuring instruments, laser interferometers, metal analyzers, ultrasonic detectors, etc., covering all aspects from material analysis to finished product inspection. These devices significantly enhance testing efficiency and accuracy, enabling the company to conduct in-depth analysis of product performance and promptly identify and resolve issues. Through the application of the intelligent detection system, comprehensive monitoring and traceability mechanisms for product quality have been achieved, ensuring high performance and excellent quality for every product.