The components of asynchronous motors need to have high strength and lightweight design to reduce energy consumption, while ensuring high precision in dimensions and fit to guarantee the stability and efficiency of motor operation; materials should have good thermal conductivity and corrosion resistance to adapt to harsh working environments such as high temperatures and humidity; in addition, the components must also comply with relevant electrical safety standards and regulations to ensure the safe and reliable operation of the motor under high voltage and high speed, and quality must be strictly controlled to improve the overall performance and reliability of the electric drive system.

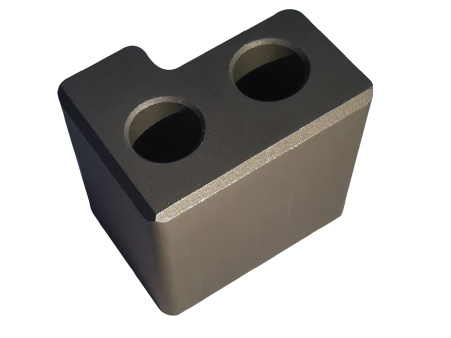

Bearing cage

The bearing cage manufacturing process covers multiple techniques such as stamping, machining, composite, injection molding, plastic coating, and casting (aluminum casting, copper casting, iron casting), capable of producing micro bearing cages with a diameter as small as 2mm for ultra-small motors, and super large bearing cages with an outer diameter of over 6m for wind turbines.

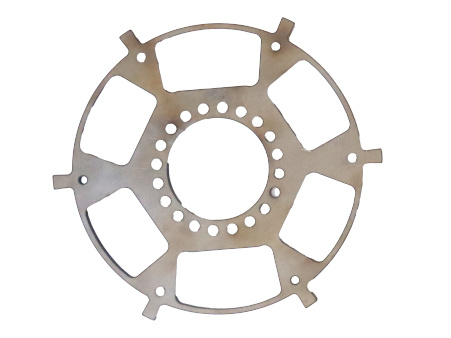

General Motors Parts

Focusing on the manufacturing of core components such as precision stamping, precision casting, precision injection molding, and machining, we have established long-term stable partnerships with global top 100 automotive parts companies like Bosch, BorgWarner, Magna, and Aisin, with our products ultimately applied in many well-known cars in the market.

Parking system

Exhaust system

Synchronizer System

Clutch system

Gear shifting system

Car door components

Seat system

Oil pump/piston system

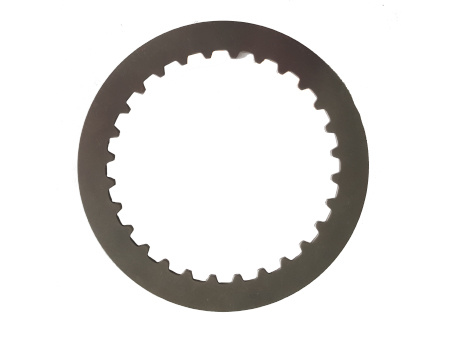

New energy vehicle parts

The company is deeply engaged in the field of core components for electric drive in new energy vehicles, focusing on innovation and breakthroughs. It specializes in providing rotor and stator processing services, relying on in-depth materials science technology and emphasizing the research of basic material innovation and application technology. The company possesses the most comprehensive testing and analysis capabilities in the industry, adopting an integrated scientific manufacturing model of 'materials-structure-process-performance-lifetime'. It offers comprehensive assessments from material testing to lifetime testing, ensuring product quality, meeting different customer needs, and continuously innovating research. Through process exploration, failure analysis, and technological iteration, the company continuously enhances product reliability.

Hydrogen energy and energy storage

As a professional manufacturer of bipolar plates in the hydrogen power field, the company's products are widely used in the automotive, marine, aviation, and energy storage sectors. They cover components in the hydrogen field such as hydrogen fuel cell bipolar plates, composite end plates, etc. (using processes like metal sheet stamping, flexible graphite molding, nano-ceramic coating, and machining injection molding), as well as alkaline electrolyzers (ALK), PEM electrolyzers, and solid oxide (SOEC) electrolyzer bipolar plates in the hydrogen production field, and all-vanadium flow battery graphite bipolar plates in the energy storage field.