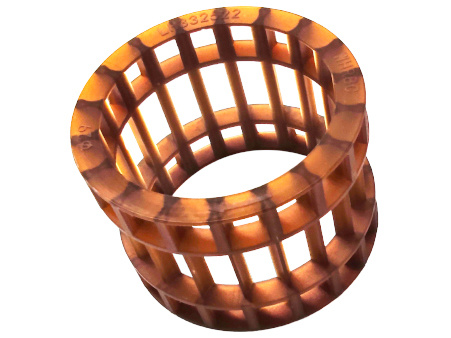

Cage for needle bearings

The cage of the needle bearing is used to guide the uniform distribution of needles in the needle bearing, ensuring smooth operation. The cage is usually made of stamped steel or engineering plastics, featuring lightweight, high precision, and low friction characteristics, making it suitable for use in confined spaces. It is widely used in fields such as automotive transmissions, engines, and aerospace.

Product advantages

- High load density: Needle roller bearings have a large number of fine needles, and the cage can arrange the needles in an orderly manner, allowing the needle roller bearings to bear a large radial load within a limited space. They are commonly used in equipment with space constraints and high load requirements, such as automotive transmissions.

- Maintain needle spacing: Effectively prevents excessive friction and wear caused by the needles contacting each other, ensuring the normal operation of the needle roller bearings and extending the service life of the bearings.

- Adapt to high-speed rotation: Some needle roller bearing cages use special structural designs or materials that can meet certain high-speed rotation requirements, such as applications in bearings for small high-speed motors.

- Compatibility with needles: The structure of the cage matches the shape and size of the needles, ensuring correct positioning and movement of the needles within the bearing, reducing rolling resistance.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy