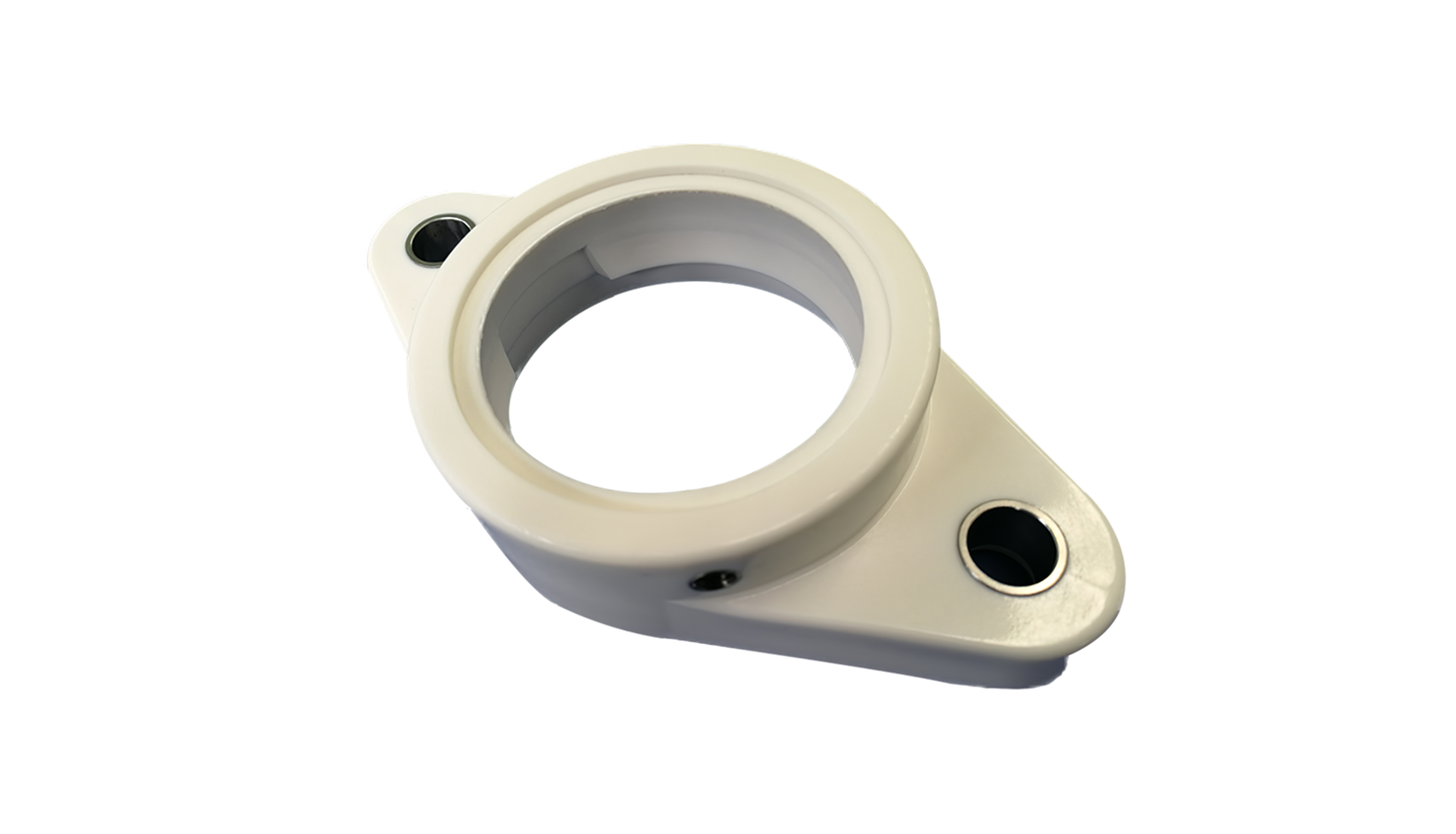

Bearing seat

The bearing housing is an important mechanical component that supports the bearing, usually made of cast iron, cast steel, aluminum alloy, or injection molded materials, with sufficient strength and rigidity to bear the weight and load of the bearing and transmission components. It is internally designed with a bearing chamber that closely fits the outer ring of the bearing, ensuring that the bearing can be installed and operate stably. The bearing housing is often equipped with sealing devices to prevent lubricant leakage and contamination.

Product advantages

- Lightweight: Injection molded bearing housings are typically made from lightweight materials such as engineering plastics, which helps reduce the overall weight of the equipment, lower energy consumption, and align with modern lightweight design trends.

- Strong corrosion resistance: Engineering plastics such asPOM,HDPE,PP,UPE,PTFEand others have good corrosion resistance, able to withstand various corrosive media and organic substances within certain temperature and concentration ranges, making injection molded bearing housings particularly suitable for chemical, pharmaceutical, and food applications that require resistance to acid and alkali corrosion.

- Easy installation: The design of injection molded bearing housings often considers ease of installation, with a compact structure that allows for a simple and quick installation process, saving time and costs.

- Maintenance-free: Injection molded bearing housings have good self-lubricating properties and high wear resistance, thus requiring almost no additional lubrication and maintenance during operation, reducing maintenance costs and time.

- Shock absorption and impact resistance: Injection molded bearing housings have better shock absorption and impact resistance compared to traditional materials, helping to protect equipment from external shocks and improving the stability and reliability of the equipment.

- Good economy: The production cost of injection molded bearing housings is relatively low, and they are easy to mass produce, which helps reduce product costs and improve economic benefits.

- Strong adaptability: Injection molded bearing housings can be made from different materials based on various usage environments and performance requirements, thus meeting the usage needs under different working conditions.

- Environmentally friendly and energy-saving: Injection molded bearing housings have a minimal environmental impact during manufacturing and use, complying with modern industrial requirements for environmental protection and energy conservation.