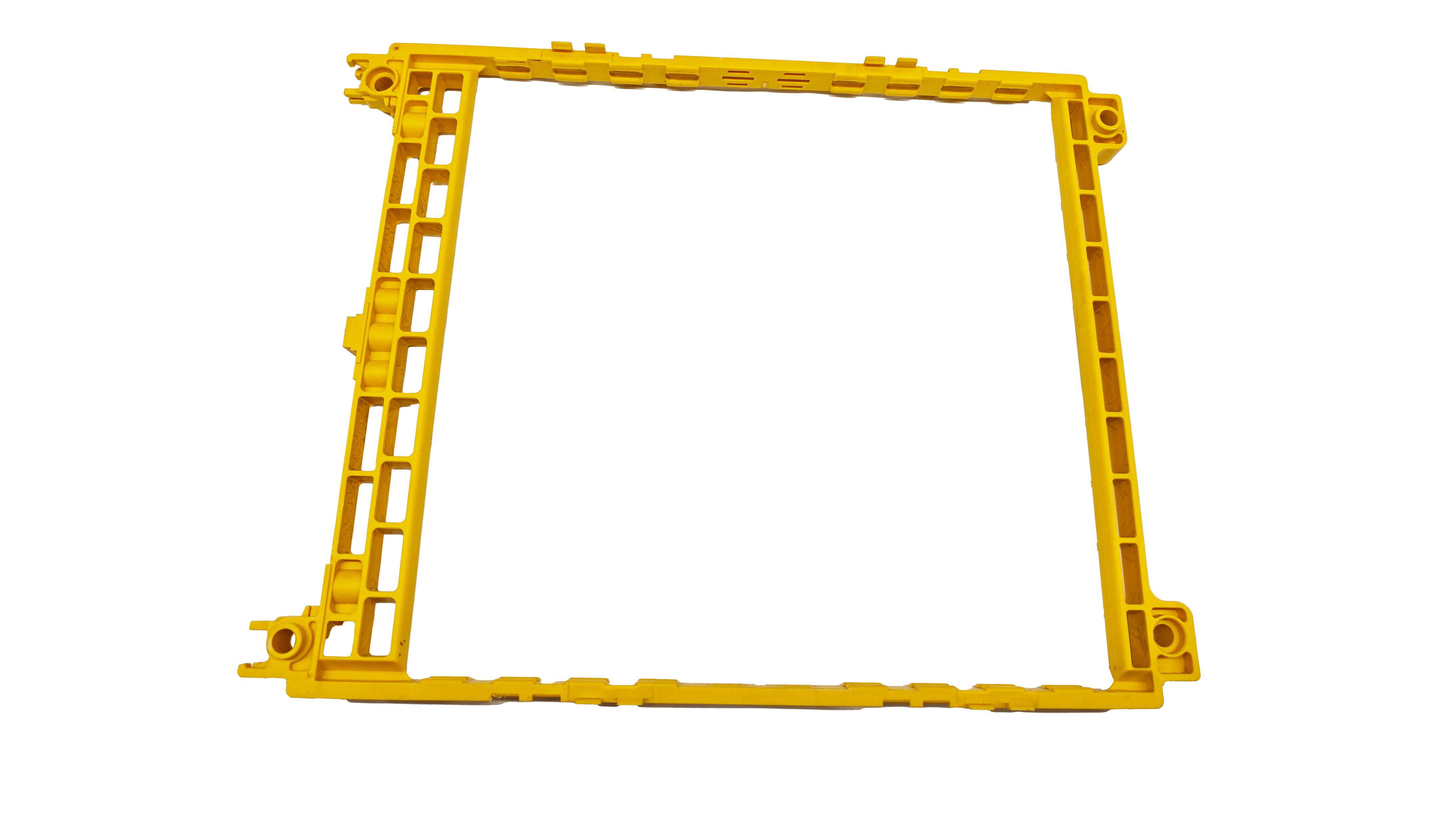

Battery pack module injection molding frame

The injection-molded frame structure has high strength, effectively protecting the battery cells and circuits; lightweight materials can reduce the weight of the battery pack and improve energy efficiency; good corrosion resistance extends battery life; at the same time, the injection molding process is highly automated, reducing costs, and the materials have good insulation properties, enhancing the safety of the battery.

Product advantages

- Lightweight: The injection-molded frame is made of lightweight materials, which helps reduce the weight of the battery pack and improve the energy efficiency of new energy vehicles.

- High strength and corrosion resistance: The materials used for the injection-molded frame typically have excellent mechanical properties and corrosion resistance, ensuring that the battery module can be used for a long time in harsh environments without damage.

- Ease of processing and manufacturing: The injection molding process has advantages such as high production efficiency, low cost, and high precision, allowing for mass production of injection-molded frames that meet requirements.

- Design flexibility: The design of the injection-molded frame can be customized according to the shape and size of the battery module to meet the needs of different new energy vehicles.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy