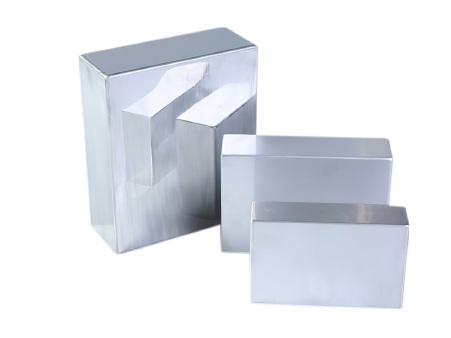

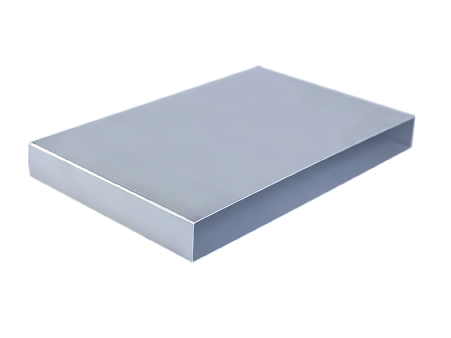

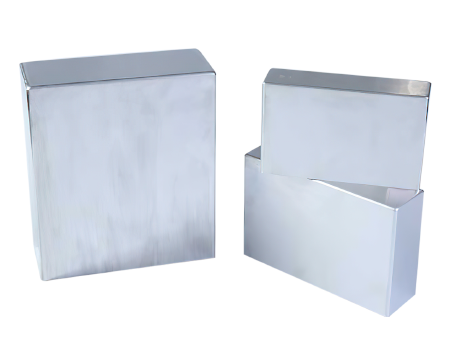

Square lithium battery aluminum shell

Aluminum shells are lightweight, easy to process, have good thermal conductivity, and are corrosion-resistant. They reduce vehicle weight and improve energy efficiency; they can be formed in one stretch, making manufacturing simple; they dissipate heat well, ensuring stable battery operation; and they are rust-resistant, suitable for various environments.

Product advantages

- Lightweight: Aluminum alloy materials have a lower density compared to traditional materials like stainless steel, allowing square aluminum shells to achieve a lighter weight, which helps reduce the overall weight of new energy vehicles and improve energy efficiency.

- High strength and corrosion resistance: Aluminum alloys such as aluminum-manganese alloys have high strength and excellent corrosion resistance, ensuring that square aluminum shells can be used for a long time in harsh environments without damage.

- Good machinability: Aluminum alloy materials are easy to process and manufacture, meeting the demand for battery aluminum shells of different sizes and shapes, thereby reducing production costs.

- Environmental protection and recyclability: Aluminum alloy is a recyclable material that meets environmental protection requirements and is beneficial for resource recycling.

- High safety: The design of the square aluminum shell takes into account the safety of the battery, improving the safety of the battery during use through reasonable structure and material selection.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy