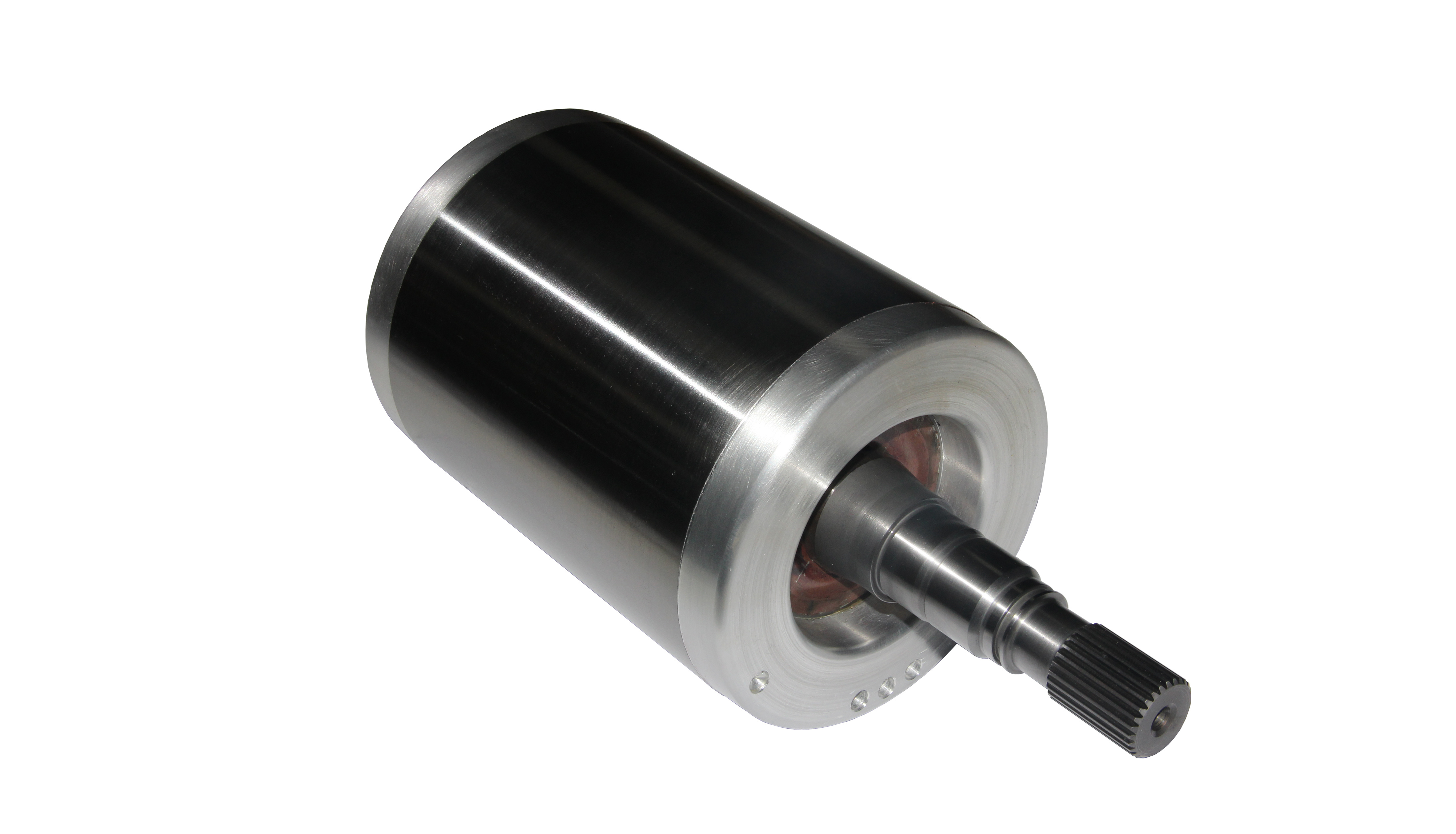

Aluminum casting rotor

The main role of the aluminum rotor in the electric drive system of new energy vehicles is to provide power output. Under the action of the rotating magnetic field generated by the stator, the aluminum rotor obtains a torque, thereby driving the motor to rotate and, in turn, driving the vehicle. The lightweight design of the aluminum rotor helps to improve the power/weight density of the motor, reduce the moment of inertia, thereby releasing greater starting torque and enhancing the vehicle's power performance.

Product advantages

- Lightweight:The density of aluminum is much lower than that of metals like copper, so aluminum rotors are lighter than copper rotors, which helps reduce the weight of the motor and the entire vehicle, improving energy efficiency.

- Low cost:The raw material price of aluminum is relatively low, and the aluminum casting process is mature, resulting in low manufacturing costs, which helps reduce the overall cost of the motor.

- Superior performance:Aluminum rotors have a small moment of inertia, allowing for quick response to control signals, enhancing the dynamic performance of the motor. At the same time, aluminum rotors can effectively reduce rotor temperature, lower the risk of demagnetization of the magnetic steel, and improve the reliability of the motor.

- Good environmental adaptability:Aluminum has good high-temperature and moisture resistance, allowing aluminum rotors to maintain good working conditions even in harsh environments.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy