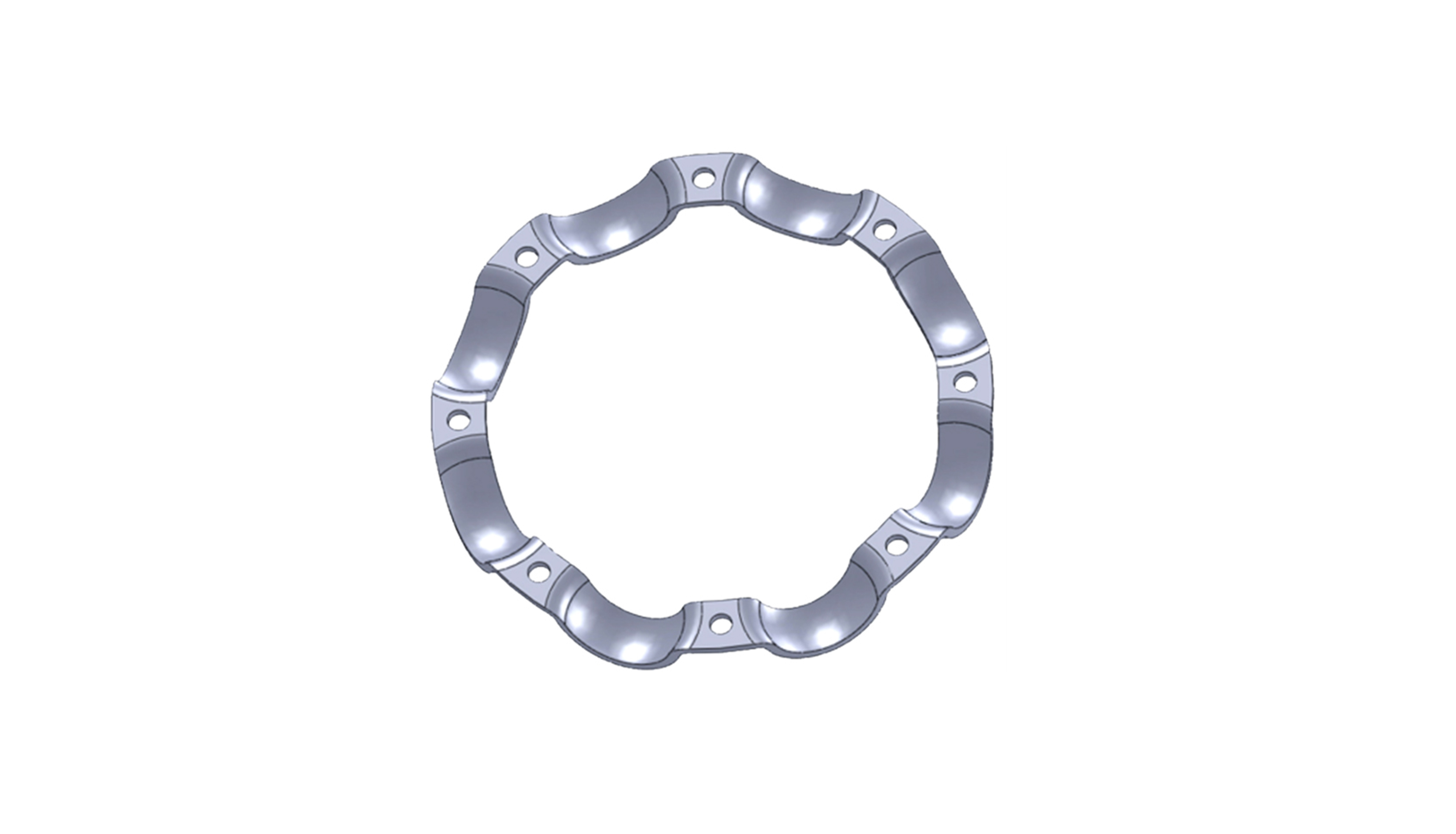

Deep groove ball bearing cage

The deep groove ball bearing cage is a key component specifically designed for deep groove ball bearings. It is mainly used to evenly separate the steel balls and guide them to move along the correct trajectory. It can prevent direct contact between rolling elements, reduce friction and wear, and improve the stability and lifespan of the bearing during high-speed operation.

Product advantages

- Material diversity and performance matching:

- Stamped steel cages have high strength and are lightweight, suitable for deep groove ball bearings under general working conditions, commonly used in medium and small deep groove ball bearings, especially in equipment with weight requirements.

- Brass cages have high tensile strength and are not affected by commonly used lubricants, suitable for deep groove ball bearings with special lubrication requirements and higher speeds, with applications in small and medium deep groove ball bearings.

- Polymeric materials (such as nylon) cages have good elasticity and self-lubricating properties, suitable for deep groove ball bearing conditions with vibration impact stress or where the inner and outer rings may tilt relative to each other.

- Stamped steel cages have high strength and are lightweight, suitable for deep groove ball bearings under general working conditions, commonly used in medium and small deep groove ball bearings, especially in equipment with weight requirements.

- Lubrication and friction aspects: Their structural design facilitates the entry of lubricants into the bearing, reducing friction and wear, ensuring long-term stable operation of the bearing.

- Load distribution characteristics: Ensures that the steel balls are evenly distributed, making the bearing more stable under radial and axial loads, improving load capacity.

- Structural and weight advantages: The stamped structure of the stamped steel cage is simple, easy to manufacture, lightweight, helps reduce the overall weight of the bearing, and is easy to mass produce and replace.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy