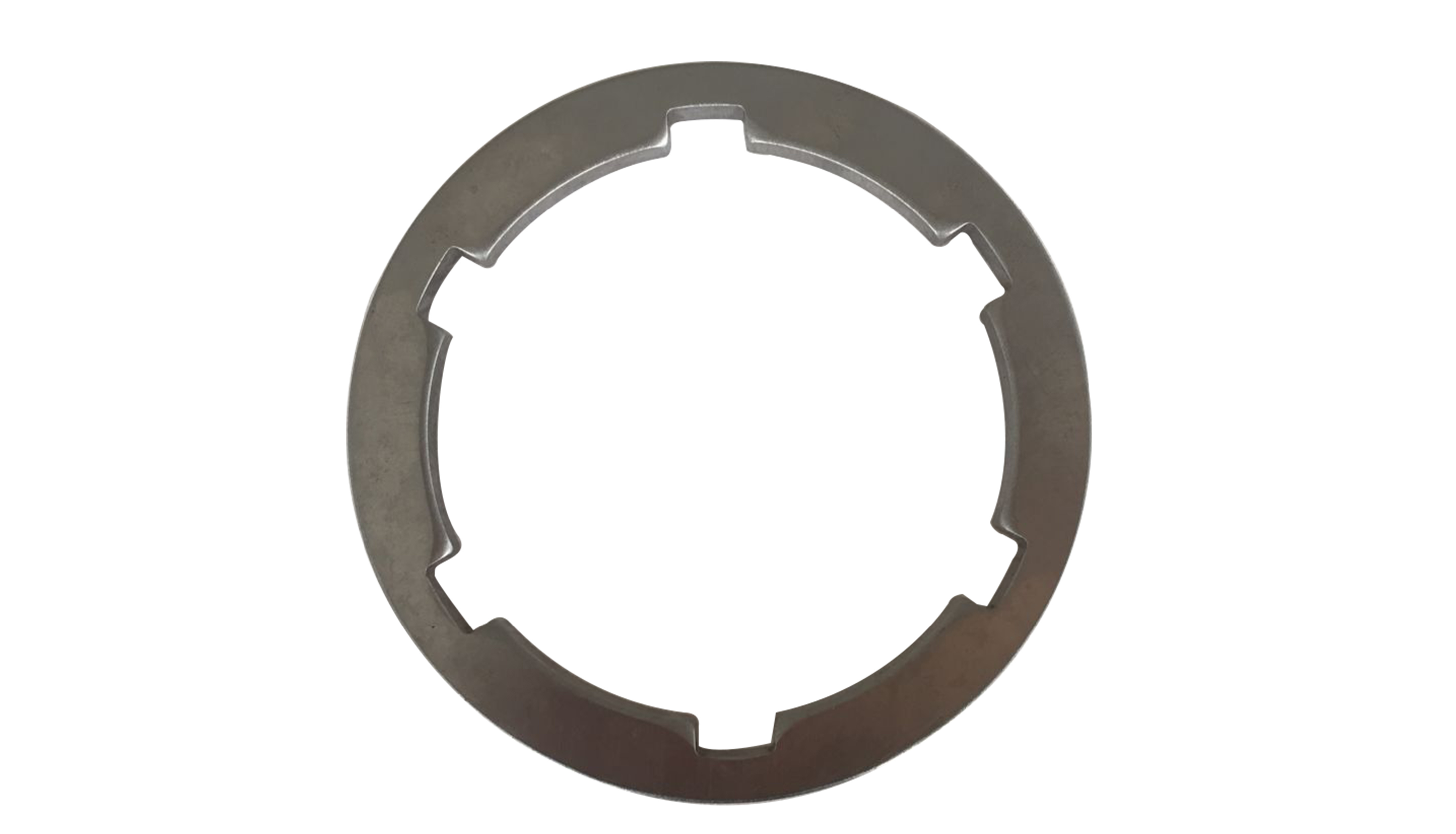

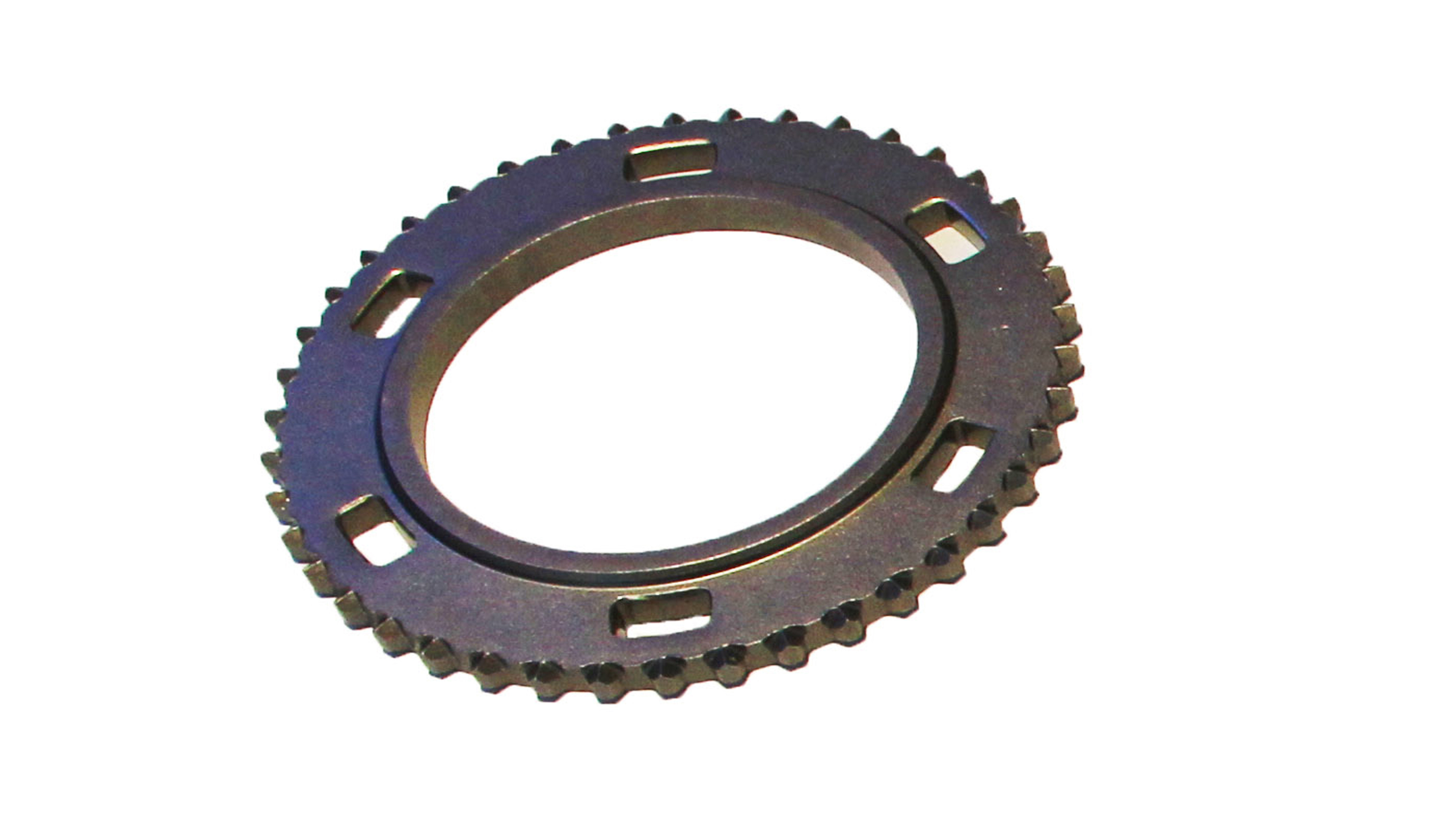

Synchronizing ring - coupling teeth

Product advantages

First, the design of its conical surface optimizes friction performance, making the synchronization process more efficient and smooth. Secondly, the material and manufacturing process of the coupling teeth have been carefully selected and optimized to ensure their stability and durability under high strength and harsh conditions. In addition, some advanced synchronizers also use special designs for the coupling teeth, such as conical surfaces with chamfers or grooves, to further improve lubrication and heat dissipation performance, enhancing synchronization efficiency and service life. These advanced design and manufacturing technologies enable the coupling teeth to play a more important and efficient role in automotive synchronizers.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy