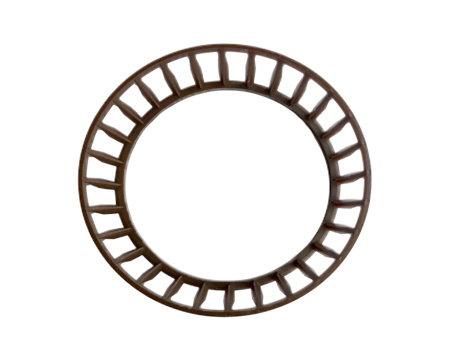

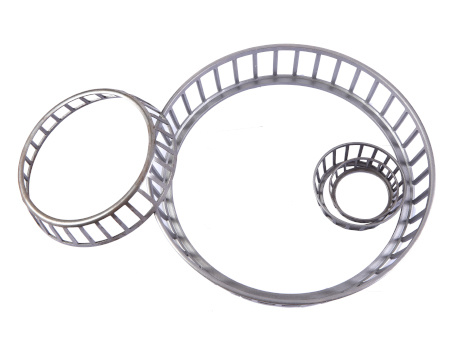

Tapered roller bearing cage

The cone roller bearing cage is used in cone roller bearings to guide the rollers and maintain an even distribution, ensuring stable operation of the bearing under combined radial and axial loads. It has high-temperature resistance and fatigue resistance, and is widely used in fields such as automotive hubs, gearboxes, and construction machinery.

Product advantages

- High load capacity: Designed to be robust, capable of bearing large radial and axial loads in tapered roller bearings, suitable for equipment such as automobiles and rolling mills that endure combined loads.

- Precise guidance and high-speed adaptability: The cage guided by the inner or outer ring provides precise guidance, ensuring stable operation of tapered roller bearings under high speeds and vibration environments (such as automotive hub bearings).

- Good lubrication performance: The cage structure facilitates the uniform distribution of lubricants, reducing friction and heat generation, which helps improve bearing efficiency and lifespan.

- Wide adaptability in material selection: Materials such as stamped metal, machined metal, or polymer plastics can be selected based on application requirements. Stamped metal cages are lightweight and cost-effective; machined metal cages are suitable for complex force-bearing situations; polymer plastic cages have low friction and are suitable for specific lubrication requirements.

- Lifespan extension characteristics: By optimizing the contact between the cage and rolling elements, wear is reduced, effectively extending the service life of tapered roller bearings.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy