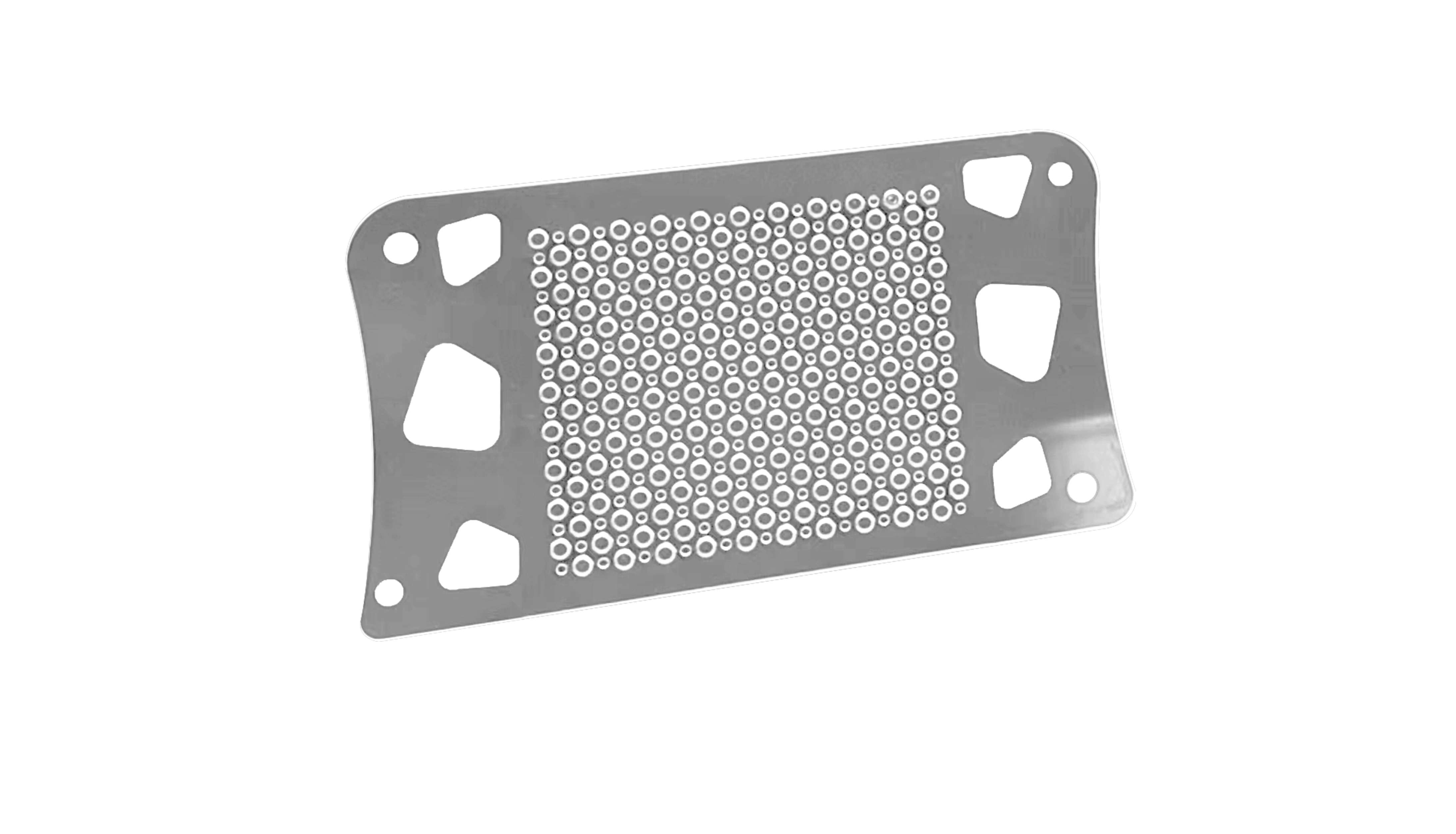

SOEC solid oxide electrolysis cell electrode plate

SOEC solid oxide electrolysis cell electrode plates not only serve as electrodes to convert electrical energy into chemical energy to drive water decomposition, but also are responsible for thermal management in high-temperature environments, hydrogen-oxygen separation to ensure the safety and efficiency of gas collection, while providing mechanical strength and structural support to ensure the stability and durability of the electrolysis cell.

Product advantages

- High efficiency:SOECThe electrolyzer operates at high temperatures (700~850℃) which provides kinetic advantages leading to higher electrolysis efficiency. High-temperature operation can accelerate the electrode reaction rate, significantly reduce the overpotentials of the cathode and anode, and effectively minimize energy losses during the electrolysis process.

- Reversibility:SOECIt has reversibility and can be used as a reversible fuel cell (rSOC) for the storage of renewable energy, forming"electricity-hydrogen-electricity"hydrogen production, storage, and power generation systems. This reversibility providesSOECbroad application prospects in energy storage and conversion.

- Wide adaptability:SOECThe electrolyzer can utilize various energy sources, including intermittent renewable energy and waste heat, enhancing the flexibility and efficiency of energy utilization.SOECThe technology can be integrated with external heat sources such as nuclear power plants, industrial waste heat, or solar collectors, further reducing hydrogen production costs.

- Low material costs: Under high-temperature conditions,SOECthe electrolyzer can use inexpensive nickel electrodes (Ni-YSZ), reducing material costs.

- Low energy consumption:SOECThe energy consumption of the electrolyzer is relatively low, especially when integrated with external heat sources, which can significantly reduce electricity consumption.

For more information, please continue to visit the subsidiary website

Address: No. 66, Zhengjia Industrial Park, Liaocheng City, Shandong Province

Phone: +86-0635-8683098

Email: salesplan@gebchina.cn

Copyright © Shandong Golden Empire Precision Machinery Technology Co., Ltd

Statement

Privacy Policy

Terms of Use

Cookie Policy